Porosity

Porosity refers to the volume of void spaces within a material, influencing its ability to absorb, retain, or transport fluids and gases. This property is critical in industries like construction, filtration, and pharmaceuticals, where porosity affects strength, permeability, and functionality.

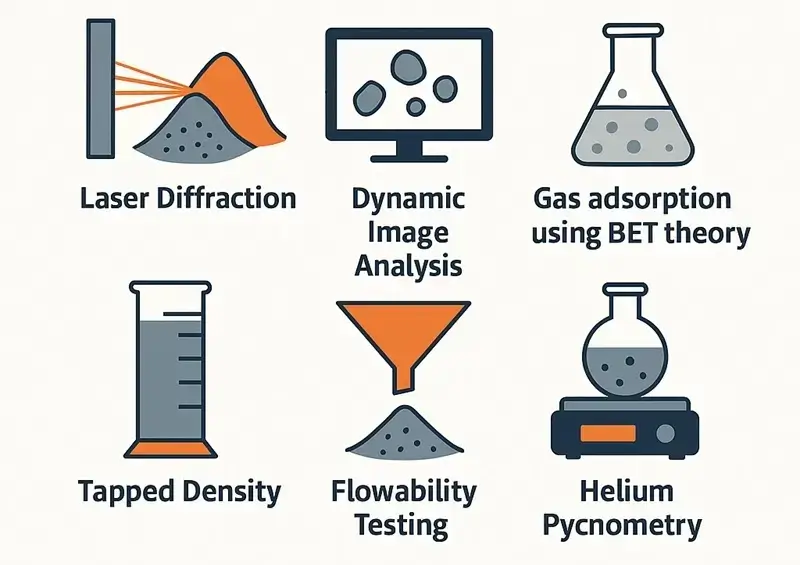

On this page, learn about the principles of porosity, its measurement techniques, and how it impacts material performance in various industrial applications.

Featured Porosity Articles

News And Articles In Your Inbox

Sign up and receive PowderTechnology.info news, articles, and content from our partners in a quick and easy monthly newsletter.