Table of contents

Introduction: Why flow tests are not interchangeable

Powder handling drives output, cost, and quality. Yet people still talk about “flowability” as if it were one thing. It is not. Flow is a bundle of behaviours that shift with moisture, charge, shape, and stress history.

Tests help, but no test does everything. A method that predicts hopper discharge will not explain feeder drift. A tidy angle test can flatter a powder that still bridges in a silo. Choose the wrong method, and you will buy trouble later.

This guide compares the main flow tests. It also shows how to match each method to real plant issues. That choice saves time, redesign, and a lot of phone calls.

Main flow test methods, and what they really measure

Ring shear testers

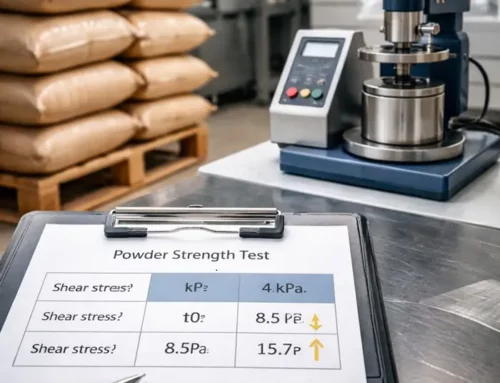

Ring shear testers measure strength under consolidation. You get a flow function, unconfined yield strength, and wall friction. Those numbers tie directly to hopper design and discharge behaviour.

You use ring shear when arching or ratholing appears. The method recreates stress states found in silos. Results support choices on hopper angles, outlet sizes, and liners. When storage is the problem, this is your primary tool.

FT4 powder rheometer

The FT4 offers dynamic testing, shear, and bulk property modules. Its dynamic mode measures flow energy during conditioning, aeration, and compaction. That speaks to mixing, dosing, and layer movement.

It also measures permeability and compressibility. Those matter for pneumatic conveying and capsule filling. If your issue is feeding drift or blend uniformity, the FT4 earns its keep.

Shear cells for compaction

Shear cells inside compactors or linked rigs track behaviour under load. They show strength gain and deformation during consolidation. That link matters for tablet quality, pellet density, and granule robustness.

Use these tests when compaction outcomes vary. You learn how the material builds strength and where failure begins.

Angle of repose and simple funnel tests

Angle tests and funnel flows give fast screens with minimal kit. They are useful for routine checks and trend watching. Still, results are operator sensitive and easily swayed by humidity and shape.

Treat these as early indicators, not design inputs. If decisions hang on these numbers, test again with a deeper method.

How the results translate to practice

-

Ring shear data predicts discharge, arching, and ratholing. You design storage with confidence.

-

FT4 dynamic data explains dosing repeatability and response to aeration. You stabilise feeders and mixers.

-

Shear cell results link consolidation to press behaviour. You set compaction windows with fewer surprises.

-

Angle tests offer quick screens. You still confirm with higher fidelity tests before you act.

I have seen silos that looked fine on paper and still stalled on site. Later, ring shear showed the real strength under stress. I have also seen feeders wander for weeks. Dynamic data then revealed that aeration and conditioning were out of tune.

Choosing the right test, a simple framework

You do not need a crystal ball. You need a clean decision path.

-

Hopper discharge problems? Use ring shear. Add wall friction tests.

-

Feeder or dosing inconsistency? Use FT4 dynamic tests under aerated and compacted states.

-

Tablet compaction or pellet density issues? Use shear cells for consolidation behaviour.

-

Quick screen or incoming QC? Use angle or funnel tests, then confirm as needed.

Small note on workflow. Start with the problem, then map the stress state. Pick the test that reproduces that state. Finally, repeat under a few humidity and consolidation levels. That pattern wins.

Industry examples that echo on the floor

Pharmaceuticals

Granules must feed cleanly and compact into strong tablets. Ring shear helps set hopper angles that avoid bridging. Shear cell data sets the compaction window. FT4 dynamic tests confirm if flow aids improve feeder stability. The trio reduces waste and downtime.

Food powders

Spray-dried milk and cocoa often cake in storage. Ring shear reveals strength growth under long hold times. Wall friction directs liner choice. Permeability explains aeration during conveying. The stack of tests tells you whether to condition, line, or redesign.

Additive manufacturing

Metal powders need even spreading in thin layers. FT4 dynamic tests show the energy needed to move and level powder. Permeability helps predict response under nitrogen flow. Angle tests can look good yet still miss spreading failure. Dynamic data closes that gap.

Cement and minerals

Big vessels hide big problems. Funnel flow leads to ratholing and segregation. Ring shear supports mass flow design from the start. Wall friction data narrows liner options for abrasive materials. Fewer surprises follow on-site.

Standards and good practice that keep data honest

Standards keep us from fooling ourselves. ASTM D6128 covers shear testing. ISO 11697 covers flowability determination. Follow the steps on sample prep, consolidation levels, and test conditions.

Then apply these good practices.

-

Test at several consolidation pressures.

-

Condition samples to stable humidity.

-

Measure more than one batch.

-

Avoid leaning on angle tests for design calls.

Skip these, and results drift. Hygroscopic powders in particular will bite you later.

Closing thoughts

low is not one property. It is a system response. Ring shear predicts storage discharge. FT4 reveals dynamic behaviour. Shear cells govern compaction. Angle tests screen, and little more.

Pick the method that fits the stress state in your process. Confirm across a few conditions. Turn the numbers into design or operating windows. Do that, and flow stops being guesswork.

Downloadable resources

To support this Know How, we prepared two reference documents that you can use directly in practice. Both are free to download as PDF.

1. Flow Test Comparison Guide

This three-page guide summarizes the most used powder flow test methods. Each method is explained in terms of what it measures, where it applies, and where it fails. The guide also includes best-practice checklists, rules of thumb, and reporting templates.

👉 Download the Flow Test Comparison Guide (PDF)

2. Flow Test Decision Framework

This three-page framework links common process symptoms to the correct test. It shows which method to use for hopper discharge issues, feeder drift, compaction failures, and quick QC. Industry snapshots and a standards list add further context.

👉 Download the Flow Test Decision Framework (PDF)

Both documents are designed as working tools. Use the Comparison Guide to understand methods side by side, and the Decision Framework to select the right test based on real process challenges.