Why changeovers hurt more in powders

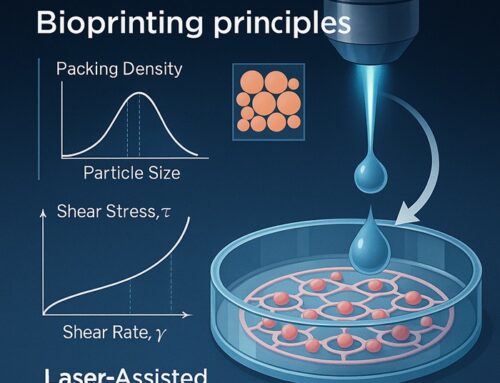

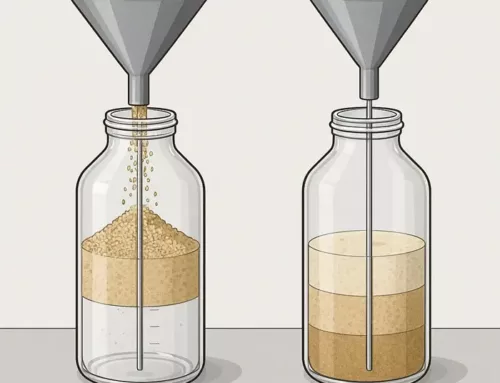

Powders behave differently from liquids. They cling to surfaces, wedge into corners, and charge electrostatically. Even a few grams left behind can contaminate the next batch. In continuous lines, this results in a hidden loss stream, including extra purge material, unplanned stops, and quality holds.

A plant running multiple grades often loses more to changeovers than to process inefficiency. Each transition involves three stages: purge, cleaning, and restart. Each one can slip if procedures are vague or hardware is hard to access. Field data show that optimizing these transitions can lift effective uptime by two to five percent, a number few operations can ignore.

Five fast wins to cut changeover losses

1. Design short, validated purge recipes

Most plants purge by rule of thumb. A better approach is a defined purge protocol built on actual data. Track the minimum air or carrier powder needed to reach purity, and lock it in as a recipe. This limits waste and standardises operator action.

2. Simplify component access

If cleaning requires tools, expect shortcuts. Replace bolted covers with captive clamps or quick-release frames. Modular hoppers and removable liners save hours when grades change often. Quick access also improves inspection and builds operator confidence.

3. Add vibration and air-scour steps

Residual fines often sit below the purge flow zone. A brief pulse of air and vibration before the main purge helps detach them. This low-cost modification can reduce purge mass by up to 20 % in fine or cohesive powders.

4. Schedule changeovers with intention

Avoid switching formulas during shift changes or near breaks. Attention drops, coordination weakens, and rework climbs. Plan transitions when teams are stable and supervision is strong. It is a procedural fix that costs nothing but improves yield.

5. Apply low-adhesion surface treatments

For sticky or oily powders, friction is the enemy. Polished or coated internals release material faster and clean easier. PTFE-based sprays, ceramic coatings, or disposable liners reduce hold-up and shorten cleaning cycles.

How to track improvement

Record purge duration, purge mass, and restart scrap for each run. A simple spreadsheet baseline shows where time and material vanish. After implementing one improvement, compare the next three changeovers. Even a modest drop in purge mass or faster restart shows progress worth capturing.

Use swab or optical checks to verify cleanliness. In food and pharma plants, acceptance limits define how much residue is tolerable. Visual checks are not enough. Analytical confirmation prevents costly rework later.

The hidden cost curve

Losses from changeovers rise nonlinearly with product mix. The more grades or batches per week, the greater the gain from discipline. A site running ten changeovers weekly can recover several tonnes per month with better planning and small mechanical upgrades. The payback period is usually less than one quarter.

Takeaway for plant teams

Continuous lines are only as efficient as their weakest transitions. Changeovers deserve the same engineering attention as blending or conveying. The best teams treat them as micro-projects with clear metrics and ownership. Start small, measure, refine, and lock in gains.