Why a stable average humidity still gives unstable powder flow

Spikes hiding inside “good” averages

Many plants proudly show stable climate logs. The average relative humidity looks safe and the air handling system seems under control. Yet hoppers still bridge on some days. Conveyors stall, tablets cap, or agglomerates grow in the dryer. Every time, people blame the powder grade, the supplier, or the equipment instead of seeing how humidity spikes powder flow behavior in real time.

Often, the real trigger hides inside the climate data. Short humidity spikes happen when a door stays open, a filter change runs late, or outside weather shifts quickly. Those peaks do not last long, but they stay long enough to wet surfaces, soften binders, or drive capillary condensation at particle contacts. The chart looks fine again after an hour, while the powder still carries the changed surface state.

Review of factors influencing food powder flowability.

Why powders “remember” short wet periods

Humidity spikes matter because powders respond locally and irreversibly. A short period above a critical relative humidity can change surface condition for the rest of the batch life. Once liquid bridges form or crystals grow at contacts, later drying does not return the original structure, even when the climate log looks normal again.

What humidity spikes actually do to powder surfaces

Surface moisture, films, and liquid bridges

A powder rarely sits in perfect equilibrium with the surrounding air. Particles lag behind every climate change. When humidity rises quickly, surfaces adsorb extra moisture. Hygroscopic ingredients may dissolve partially, forming thin liquid films. Even less hygroscopic materials can develop micro-scale liquid bridges in narrow pores and contact points.

Because those films and bridges increase adhesion, they change flow behavior before bulk moisture measurements move. A short spike can raise unconfined yield strength while the measured loss on drying stays within specification. The lab report says there is no change, while operators see a completely different hopper.

Formulation and temperature effects

Humidity spikes also interact with formulation. One component may respond strongly, while another remains almost unchanged. In multi component blends, that leads to selective softening, local sticking, or growth of fragile agglomerates. Segregation patterns shift because some fractions clump while others stay free flowing. The system becomes harder to predict and control.

Temperature adds another layer. Warm, humid air holds more water and accelerates diffusion into pores and surface layers. A spike at higher temperature drives faster changes in the same short window. That pattern explains why summer storms often correlate with flow issues, even in air conditioned plants.

Where humidity spikes hide in your process

Warehouse and loading hotspots

Most plants monitor climate in a few central locations. The data looks smooth and controlled at those points. Unfortunately, powders pass through many micro environments that rarely see sensors. Each one can generate local humidity spikes.

Warehouse doors open for loading and remain open longer than intended. External air floods the area around certain pallets. The average sensor, mounted high and far away, sees only a small bump. Powders near the door experience a sharp rise in humidity combined with drafts and temperature swings.

Local climates at transfer and discharge points

Transfer points create another hidden zone. When sacks open or big bags discharge, dust clouds form around the inlet. Local air becomes richer in fine particles and may saturate with moisture from the powder itself. Small enclosures around feed hoppers trap that air and amplify short term spikes.

Dryer outlets and coolers can also contribute. If cooling air changes temperature or humidity during a filter change, partially dried granules may reabsorb moisture on the way to the bin. Similarly, poorly drained condensate in air ducts can create transient wet spots in the airflow, which then pass across powders on screens or belts.

Simple ways to see and measure humidity spikes

Use fast, local sensors where powder matters

You cannot manage what you never see. However, you do not always need an expensive monitoring project. A few practical steps already reveal most humidity spikes.

First, place at least one fast responding humidity logger near the most sensitive powder location. That might be the outlet of a critical hopper, the bag dumping station, or the inlet of a key blender. Logging at one-minute intervals shows a structure that fifteen-minute averages hide completely.

Second, align humidity logs with production events. Mark times when doors open, equipment stops, filters change, or cleaning occurs. When trends overlay with these events, you find real causes for several long-running powder problems.

Correlate climate, events, and flow behavior

Third, compare climate trends with flow and quality records. Note when line pressure rises in pneumatic conveyors or when the discharge time from a hopper test stretches. Look for spikes that precede those changes by tens of minutes, not hours. That window often matches the time powders need to respond.

Finally, strengthen basic housekeeping. Simple actions, such as closing doors promptly and separating climate zones with curtains, reduce extreme peaks. Operators need to understand that short periods of non ideal humidity can still have lasting effects on powder flow.

Turning humidity spikes into a design parameter

Define a safe humidity window for each powder

Once you can see humidity spikes, you can design around them. The first step involves defining a safe window for each critical powder. That window combines relative humidity, temperature, and exposure time. Outside that window, behavior will likely drift.

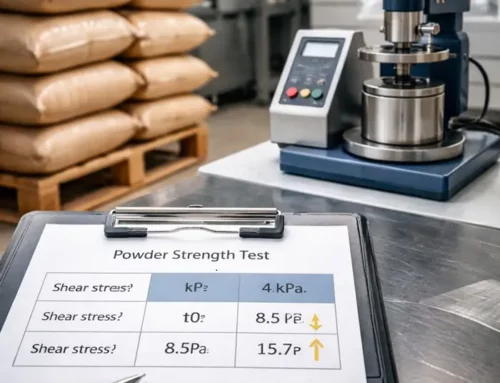

To find that window, you can run small storage tests at different humidity levels using sealed chambers with controlled air. Measure flow, strength, or caking behavior after defined exposure times. Pay special attention to early changes that appear with short spikes. Those conditions mark the boundaries that matter most in daily practice.

Convert insight into simple operating rules

Next, translate that knowledge into simple rules for operations. For example, you might require that big bag discharge only occurs when local humidity stays inside the safe window. You might also define maximum open door times for connecting corridors near sensitive hoppers. Those rules should rely on clear numbers and simple displays, not vague impressions.

Because humidity spikes powder flow behavior in complex ways, you rarely eliminate them completely. Instead, you build resilience. You schedule the most sensitive steps at times when climate remains stable. You avoid combining vulnerable powders with known seasonal spikes unless you adjust formulations or processing conditions.

Over time, this approach changes how teams talk about powder problems. Instead of blaming bad luck or difficult batches, people discuss specific humidity events, safe windows, and exposure histories. That language invites measurement, control, and improvement.