Powder permeability dosing instability rarely looks like a gas problem. It looks mechanical. The hopper pulses. The screw hunts. The loss in weight rate drifts for no obvious reason. However, air inside the powder bed often drives the chaos.

Air sits between particles and moves when the bed shears. That movement changes local density and effective stress. Consequently, the powder can switch behavior mid run, even with unchanged settings.

What permeability really tells you

Permeability describes how easily gas flows through a packed powder bed. (Here is a deeper technical review on permeability in granular beds and powders). High permeability lets air escape quickly. Low permeability traps air, then releases it in bursts.

That is why a powder can pass a simple flowability screen, yet still dose poorly. Many routine tests do not excite the same gas pathways as refill and discharge. In contrast, a feeder inlet constantly forces air to enter and leave the bed.

Permeability also depends on compaction state. A gently poured sample behaves differently than a bed that sat under head pressure for hours. Therefore, the same powder lot can look “fine” in one test and unstable in production.

Three air driven failure modes that mimic bad flow

1) Flooding that comes and goes

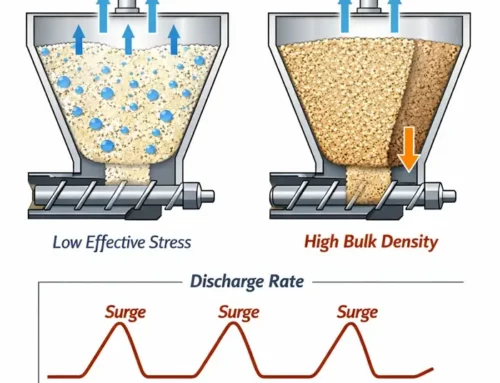

Trapped air can reduce effective stress near the outlet. The bed loosens, then collapses. As a result, you see cycles of too much feed, then starvation.

This pattern often appears right after a refill or restart. It also gets worse when you push for higher throughput.

2) Feeder surging and rate drift

A gravimetric feeder needs a stable inlet condition. It assumes the bulk density at the screw stays consistent. However, trapped air changes that density continuously.

Therefore, the controller corrects, overshoots, and corrects again. Operators call it hunting. The bed is simply breathing.

3) False bridging with sudden release

Low permeability beds can hold an arch longer than expected. Then a small disturbance releases trapped air. The arch fails, and the hopper dumps a slug.

People blame vibration or a bad lot. Yet the bed often fails because its gas pressure state changed.

Where air gets into your process

Air enters the bed through fill streams, vent lines, and leak paths. It also enters through the powder itself during dilation. Meanwhile, air must leave through vents, filters, and any free surface.

When those pathways mismatch, dosing becomes unstable. For example, you can have excellent filtration yet poor vent placement. You can also have sufficient vent area, yet a powder bed that blocks flow.

Read how to Select and Compare Powder Flow Test Methods

How to test permeability in a practical way

Start with the plant patterns, not the lab instrument.

Ask these three questions and write down the answers:

-

Does instability start right after refill or restart?

-

Does it worsen at a higher feed rate?

-

Does it improve after a short wait or steady running time?

If you answer “yes” to any of them, permeability belongs on your shortlist.

Next, measure permeability under controlled packing states. If you use an FT4 or a similar platform, run permeability at multiple consolidation levels. If you do not, use a pressure drop style method with controlled bed height and loading.

Either way, control these variables every time:

-

Moisture or water activity, if it matters for the powder

-

Conditioning and pre shear routine, so you fix the bed history

-

Sample loading method, since pour height and vibration change voidage

Without that discipline, permeability data looks noisy. With it, the data becomes predictive.

Fixes that stabilise dosing without endless tuning

Permeability is not a knob you turn. Instead, you manage how air enters and exits the bed.

Improve venting, where it actually matters

Place venting near the regions that displace air during refill and discharge. Avoid long dead legs that trap fines. Also, check filters, because clogged media turns good venting into a sealed system.

Change refill behaviour before changing hardware

Fast refill can trap air and reset the bed structure. Therefore, adjust refill height, stream velocity, and staging. Even a short refill pause can help the bed settle.

Use aeration carefully, and keep it clean

Aeration pads can stabilise discharge, yet they can also trigger flooding. Use low, controlled flow and dry air when required. Additionally, maintain the pad, because partial blockage causes uneven air distribution.

Reduce uncontrolled vibration

Vibration can densify some powders and loosen others. It also triggers episodic gas release. Consequently, random vibration often increases drift, even when flow improves.

Stabilise packing state before precision dosing

For sensitive feeders, add a controlled settling period after refill. Alternatively, use a repeatable conditioning routine before production starts. This step often beats another control loop tweak.

A fast diagnostic you can run this week

Pick one troublesome powder and one feeder that frequently drifts. Then run two short trials.

Trial A: refill, then restart immediately.

Trial B: refill, wait ten minutes, then restart.

If Trial A surges and Trial B stabilises, air and packing state drive the issue. At that point, venting and permeability testing will give you faster wins than screw geometry changes.

What to do with the result

If permeability is low and instability matches refill patterns, fix air pathways first. Then verify again under the same operating routine. Finally, tune the feeder once the inlet condition stays stable.

That sequencing saves time. It also prevents “fixing” a feeder that was never the root cause.