Table of Contents

Particle Engineering Techniques – an introduction

Particle engineering goes beyond merely shaping particles—it actively tailors them to meet specific process or product requirements. As discussed in Part One, this field empowers manufacturers to fine-tune powder behavior for optimal results. In this article, we now turn our focus to the core techniques that drive modern powder processing forward: fluid bed agglomeration, spray-drying, encapsulation, and blending.

Collectively, these methods form the foundation of effective particle control. They play a vital role in the food, feed, and pharmaceutical industries, where powder properties directly influence product success. By enhancing flowability, stability, solubility, and dosing accuracy, these techniques ensure reliable, high-performing powders. As a result, particle engineering continues to prove itself as the industry’s true “golden goose”—delivering consistency, quality, and competitive advantage.

What Are Particle Engineering Techniques?

Particle engineering techniques involve actively modifying the size, shape, surface properties, and internal structure of powders. Manufacturers select these techniques based on the specific performance needs of the final product. For example, they often aim to:

-

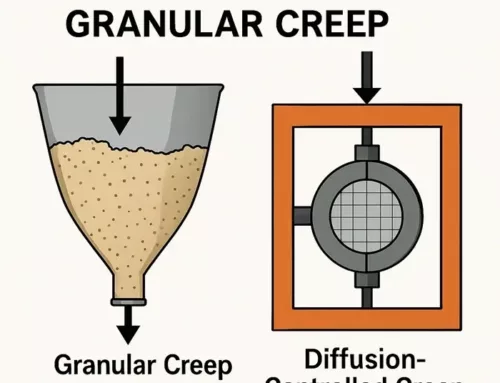

Enhance powder flow in hoppers, silos, or feeders

-

Improve mixing uniformity for better blend consistency

-

Accelerate dissolution rates in food or pharmaceutical applications

-

Increase resistance to environmental factors like moisture, heat, or oxidation

By choosing the right method for the right purpose, engineers can significantly boost both process efficiency and product stability. In the sections that follow, we’ll explore three essential particle engineering processes—fluid bed agglomeration, spray-drying, and blending—that play a key role in delivering reliable, high-performance powders.

Fluid Bed Agglomeration: Building Better Granules

Particle engineering techniques involve actively modifying the size, shape, surface properties, and internal structure of powders. Manufacturers select these techniques based on the specific performance needs of the final product. For example, they often aim to:

-

Enhance powder flow in hoppers, silos, or feeders

-

Improve mixing uniformity for better blend consistency

-

Accelerate dissolution rates in food or pharmaceutical applications

-

Increase resistance to environmental factors like moisture, heat, or oxidation

By choosing the right method for the right purpose, engineers can significantly boost both process efficiency and product stability. In the sections that follow, we’ll explore three essential particle engineering processes—fluid bed agglomeration, spray-drying, and blending—that play a key role in delivering reliable, high-performance powders.

How it works

During this wet granulation process, the system first suspends the powder particles in air. Next, it sprays a binding liquid onto the airborne particles. As a result, the droplets cause the fine particles to stick together, forming agglomerates. Then, heated air flows through the system and dries the newly formed granules.

Key Challenges

During fluidization, particle collisions frequently cause attrition, breaking down growing granules. Consequently, this leads to irregular particle sizes, generation of fines, and increased dusting.

To address these challenges, engineers actively adjust airflow velocity, binder concentration, and spray-nozzle parameters (pressure, position, and droplet size). When controlled properly, these adjustments yield granules with consistent size and enhanced mechanical strength.

Spray-Drying: Encapsulation and Homogenization in One Step

Spray-drying is a versatile technique that serves two major purposes in particle engineering: encapsulation and ingredient blending.

1. Encapsulation via Spray-Drying

Spray-drying encapsulates sensitive ingredients, such as flavors, vitamins, enzymes, or oils, in a protective shell.

How it works

-

A suspension is prepared using amphipathic agents like modified starches or proteins.

-

This suspension is atomized into fine droplets inside a heated spray-drying chamber.

-

The moisture evaporates instantly, forming solid microcapsules around the core materials.

Benefits

-

Protects active ingredients from heat, oxygen, or light

-

Enhances shelf life and stability

-

Enables controlled release in the final application

2. Blending with Spray-Drying (Infant Formula Example)

In the infant formula industry, spray-drying plays a key role in ensuring consistent blending of components such as milk powders, vegetable oils, vitamins and minerals, as well as lactose and whey proteins.

First, the ingredients are mixed, then homogenized, and subsequently pasteurized. Afterward, the final slurry enters the spray dryer, where it transforms into a uniform powder. This process guarantees even nutrient distribution across every particle.

The Importance of Blending: Enhancing Homogeneity Before Final Processing

Blending is often the first step in particle design, ensuring that ingredients are evenly distributed before encapsulation, spray-drying, or granulation.

Blending is particularly crucial for:

-

Nutraceuticals, where dose precision is vital

-

Flavored powders, where uniformity affects taste and appearance

-

Pharmaceutical powders, where improper blending can cause drug content variation

While high-speed blenders work well for free-flowing powders, cohesive powders may require specialized mixers like tumble blenders or paddle mixers to avoid segregation.

Why These Techniques Matter

Fluid-bed agglomeration, spray drying, and blending all build on one another to produce powders with better flow, precise solubility and release, enhanced moisture and oxidation stability, and consistent dosing and appearance.

Moreover, in industries where powder uniformity drives quality, these techniques form the essential foundation of production.

Recap: From Particle Design to Product Performance

In Part One, we introduced the role of particle engineering in improving product functionality. Now, in Part Two, we’ve explored the real-world techniques that make this possible.

- Fluid bed agglomeration shapes powders into functional granules

- Spray-drying enables both encapsulation and nutrient blending

- Blending ensures uniformity and consistency at the formulation level

Together, these methods support better product performance, stability, and efficiency—making them true cornerstones of the particle engineering golden goose.

Coming Next: Advanced Tools in Particle Engineering

In Part Three, we’ll explore the next-generation tools shaping particle engineering. Specifically, we’ll discuss real-time particle analysis (PAT), predictive modeling and simulation, AI-powered formulation design, and conclude with industry case studies that apply data-driven methods.

Looking ahead, the future of particle engineering extends beyond simply controlling particles. Instead, it increasingly centers on using intelligent systems to design better powders from the ground up.