Functional powder design plays a fundamental role in numerous industries. It enhances the effectiveness and efficiency of products we encounter daily. Customizing powders for specific applications enables optimization of their performance. As a result, manufacturers achieve superior outcomes across a wide range of products.

For example, formulating detergents that clean more effectively improves household chores. Additionally, paints that provide smoother finishes enhance aesthetics. Furthermore, feeds that maximize nutrition support animal health, while food additives enhance flavor and texture.

This fine-tuning of particle characteristics empowers manufacturers to meet diverse consumer needs. Importantly, this customization goes beyond aesthetics; it represents a scientific endeavor. It marries material science and engineering principles with a deep understanding of product functionality in real-world scenarios.

The Critical Role of Particle Size and Distribution in Functional Powder Design

Functional powder design starts with particle size and distribution. These are fundamental factors that define the performance of powders across various applications. In the realm of material science, achieving the precise particle size is both a science and an art.

Particle size is typically measured in micrometers (µm) or nanometers (nm), depending on the application’s requirements. For example, finer particles often enhance solubility and reactivity, while larger particles may improve flowability and packing density.

Moreover, the distribution of particle sizes also plays a crucial role. A narrow particle size distribution ensures uniform behavior in processes, leading to consistent product performance. In contrast, a wide distribution can introduce variability, impacting the final product’s effectiveness.

Functional Powder Design in the Nanometer Range

The Role of Particle Size in Paint Applications

In applications like paints, larger particles, often in the micrometer range, contribute significantly to texture, coverage, and overall aesthetic appeal of the final product. These particles help create the desired finish and improve the paint’s hiding power, ensuring an even application.

Achieving the ideal particle size involves a combination of mechanical processes, such as milling and grinding, along with precise classification techniques. High-energy mills, which employ intense mechanical forces, play a crucial role in this process. These mills effectively reduce particle size while maintaining the quality and properties of the material.

Additionally, classification techniques separate particles based on size, ensuring that the final product has the desired distribution. By carefully controlling these processes, manufacturers can optimize the performance and appearance of paints, demonstrating the importance of particle size in functional powder design.

Techniques for Particle Size Reduction

Mechanical forces, such as those employed by jet mills, utilize high-velocity fluid streams to break down larger particles into the desired size range. This method is particularly effective for achieving fine particle sizes in functional powders.

However, controlling particle distribution requires meticulous attention to process parameters. Key factors include milling time, feed rate, and classifier settings, all of which play pivotal roles in determining the final particle size distribution.

To achieve consistent and reproducible particle sizes, manufacturers must fine-tune these parameters carefully. This attention to detail is essential for maintaining product quality and optimizing performance in various applications, from paints to detergents.

The Importance of Customizing Particle Size

By customizing particle size, industries can fine-tune their products to meet specific consumer specifications and performance expectations. This capability underscores the importance of particle engineering across a multitude of applications.

For instance, in the pharmaceutical industry, precise particle sizes can enhance drug solubility and bioavailability. In food production, they can improve texture and flavor delivery. Similarly, in coatings and paints, tailored particle sizes contribute to better coverage and finish quality.

Ultimately, the ability to manipulate particle size allows manufacturers to innovate and adapt their products, ensuring they align with market demands and enhance user satisfaction. Thus, particle engineering emerges as a critical factor in driving product effectiveness and competitiveness in various sectors.

Designing Functional Powder Characteristics

In the process of designing particle characteristics for various applications, it is crucial to consider the physical and chemical attributes of powder particles. These attributes significantly influence particle behavior and overall performance.

Moreover, controlling porosity can affect the absorption and release rates of active ingredients in applications like pharmaceuticals and food additives. Similarly, adjusting surface area and surface charge can influence interactions with other materials, impacting dispersion and stability.

Ultimately, a thorough understanding of these characteristics allows for the optimization of functional powders, enabling products to meet diverse consumer needs and performance expectations. By focusing on the design of particle characteristics, industries can enhance product quality and effectiveness across various applications.

The Impact of Particle Shape and Porosity on Powder Performance

Particle shape plays a prominent role in powder behavior. Spherical particles demonstrate optimal flow properties, allowing for easier movement and processing. In contrast, irregularly shaped particles often suffer from reduced flowability due to interlocking and increased friction, which can hinder efficient handling.

Moreover, particle shape significantly affects packing density. Higher packing density contributes to improved stability and reactivity of the powder. When particles pack closely together, they create a more stable structure, which can enhance the material’s performance in various applications.

Porosity is another key factor influencing particle behavior. Porous particles boast a larger surface area compared to their non-porous counterparts, which enhances their reactivity and ability to absorb liquids or gases. This increased surface area allows for better interaction with other materials, improving the effectiveness of powders in applications such as catalysts and drug formulations.

The Role of Porosity in Particle Strength and Reactivity

Increased porosity can enhance the dissolution and reactivity of powders. However, it’s important to note that higher porosity may compromise particle strength, making them more vulnerable to breakage. This trade-off highlights the need for careful consideration when designing functional powders.

Surface area, measured as the total surface area of all particles in a powder sample, is another crucial factor to consider. Here, reactivity and dissolution properties play key roles. Powders with high surface areas are generally more reactive and exhibit superior dissolution characteristics.

Despite these advantages, powders with high surface areas also pose challenges in handling and storage. Their increased tendency for caking and agglomeration can complicate processing and application. Therefore, manufacturers must balance the benefits of high surface area with the potential issues it may cause, ensuring optimal performance while minimizing operational difficulties.

Challenges with High Surface Area Powders

High surface area powders enhance reactivity and dissolution characteristics. However, they also pose challenges in handling and storage due to their propensity for caking and agglomeration.

The surface charge on particle surfaces significantly influences powder behavior. Particles with similar surface charges tend to repel each other, which enhances flowability. This repulsion allows for smoother movement and easier processing.

Conversely, particles with opposite surface charges may attract each other. This attraction can lead to caking and agglomeration, complicating handling and reducing overall efficiency. Understanding and managing surface charge is therefore crucial in optimizing powder performance and preventing issues related to flowability.

Tailoring Particle Characteristics for Industry Needs

To provide practical examples, additives for paints greatly benefit from controlled particle porosity. This optimization improves pigment dispersion and ensures color consistency, enhancing the overall quality of the final product.

In the food industry, particle characteristics in food powders can be optimized through processes like milling and grinding. These methods enhance flowability, ensuring smooth processing during production. Additionally, increasing porosity using techniques like spray drying can improve dissolution rates, leading to better overall product performance.

Optimizing Particle Characteristics in Pharmaceuticals and Catalysts

In the pharmaceutical field, similar processes can significantly enhance dissolution rates and stability. By tailoring particle size, shape, and porosity, manufacturers can ensure that active ingredients dissolve efficiently, leading to improved bioavailability and therapeutic effectiveness.

Additives for paints also benefit from controlled particle porosity and surface charge. These characteristics enhance pigment dispersion and color consistency, resulting in higher-quality finishes and better performance in various applications.

Catalysts can achieve improved activity and selectivity through precise control of particle size, shape, and surface area. Employing advanced particle formation and coating techniques allows manufacturers to optimize these attributes, leading to more effective catalytic processes in chemical reactions.

Preventing Agglomeration in the Powder Industry

Agglomeration in the powder industry disrupts the smooth flow of particles and reduces solubility. This unintended consequence causes disturbances in particle dispersion, ultimately affecting process efficiency and uniformity.

To combat this issue, manufacturers can tailor agglomeration-inhibiting characteristics by manipulating particle size and shape. Designing particles to be smaller and more uniformly shaped reduces their tendency to cluster, allowing for better material dispersion.

Additionally, integrating this particle engineering approach with techniques like surface modifications and moisture control helps address agglomeration challenges. This combined strategy ensures smoother processes and enhances overall product quality and performance in the powder industry.

Testing and Validation of Powder Formulations

The development of a new powder formulation involves a series of comprehensive tests to ensure the powder performs as intended and remains stable. These tests encompass a range of essential properties specific to the application, providing critical insights into the formulation’s effectiveness.

Flowability is a fundamental characteristic that significantly influences the handling and processing of powders. We assess flowability using techniques like the angle of repose and Hausner ratio, which gauge the ease of powder flow. These assessments help identify how well the powder will behave during processing.

Particle size distribution is also crucial for powder performance and functionality. We measure this distribution through methods such as laser diffraction and microscopy, allowing us to understand how particle size impacts various applications.

Evaluating Bulk Density and Moisture Content in Powder Formulations

Bulk density serves as another important indicator, representing mass per unit volume. We determine bulk density by measuring both mass and volume, which is vital for effective powder handling and processing. Furthermore, moisture content is a critical factor affecting stability and performance. We evaluate moisture content through methods like Karl Fischer titration and oven drying, which help us ascertain the water content in the powder.

By thoroughly testing these properties, manufacturers can ensure that their powder formulations meet the necessary specifications for quality and performance. This rigorous validation process ultimately leads to more reliable and effective products in various applications.

Comprehensive Testing for Powder Formulation Development

The development of a new powder formulation involves a series of comprehensive tests to ensure optimal performance and stability. These tests focus on essential properties specific to the application, helping manufacturers refine their formulations effectively.

Flowability is a fundamental characteristic that significantly influences the handling and processing of powders. We assess flowability using techniques like the angle of repose and Hausner ratio. These methods gauge the ease of powder flow, allowing us to determine how well the powder will behave during processing.

Key Factors Influencing Powder Performance: Particle Size Distribution, Bulk Density, and Moisture Content

Additionally, particle size distribution is crucial for powder performance and functionality. We measure this distribution through methods such as laser diffraction and microscopy. These techniques provide valuable insights into how particle size impacts various applications.

Bulk density serves as another important indicator, representing mass per unit volume. We determine bulk density by measuring both mass and volume, which is vital for effective powder handling and processing.

Furthermore, moisture content significantly affects stability and performance. We evaluate moisture content through tests like Karl Fischer titration and oven drying, which help us determine the water content in the powder.

Stages of Powder Formulation Development

Initial Formulation:

In this stage, we define the key attributes of the powder, such as particle size distribution, flowability, and bulk density. The formulator then selects the appropriate combination of raw materials and processing steps to achieve the desired powder properties.

Prototype Development:

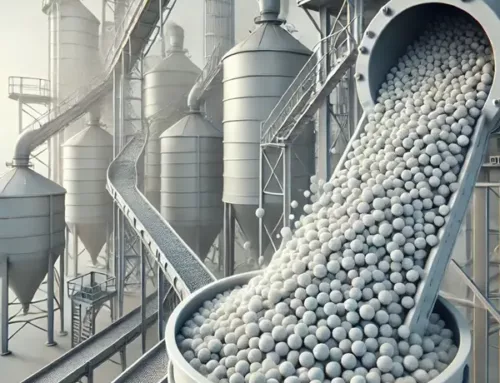

Once the initial formulation is ready, the next step involves producing a small quantity of the powder for property testing. We can use various methods for this purpose, including ball milling, spray drying, or freeze drying.

Comprehensive Testing:

The prototype powder undergoes thorough testing to ensure it aligns with target specifications. Tests may include particle size analysis, flowability assessments, and bulk density measurements to evaluate the prototype’s performance.

Optimization:

If the prototype doesn’t meet all desired specifications, we adjust the formulation and iterate the process. This step continues until we obtain a satisfactory powder with the desired properties.

Scale-Up:

After achieving a satisfactory formulation, the next phase is to scale up the process for commercial production. This might involve designing and constructing new equipment or modifying existing setups to accommodate larger batches.

The Canvas of Particle Engineering

In the intricate world of particle engineering, the canvas is as small as a grain of sand, yet the possibilities are vast. Each tailored particle silently crafts the essence of our products, ranging from efficient detergents to vibrant paints. We can consider it an unspoken symphony, where particles, like skilled musicians, perform their roles in perfect harmony.

As you explore this realm, envision the potential for innovation that lies within these minuscule building blocks. This uncharted territory evokes a sense of wonder and curiosity.

The ability to manipulate particle characteristics opens doors to new applications and improved product performance, inspiring continued exploration and creativity in the field of material science. Through particle engineering, we shape the future, one tiny grain at a time.