Table of contents

Lessons of deep-sea particle dynamics for powder engineering

Globally, the ocean covers about 71% of the Earth. It holds most of Earth’s surface water. Therefore, scale effects shape particle fate worldwide. However, hadal zones remain poorly measured. These regions lie between 6,000 and 11,000 meters. Their area is small, yet their role is distinct in deep-sea particle dynamics and natural powder engineering. Specifically, trenches collect, sort, and rework particles. For powder engineers, the physics feels familiar. Aggregation, density contrast, shear history, and surface energy set outcomes.

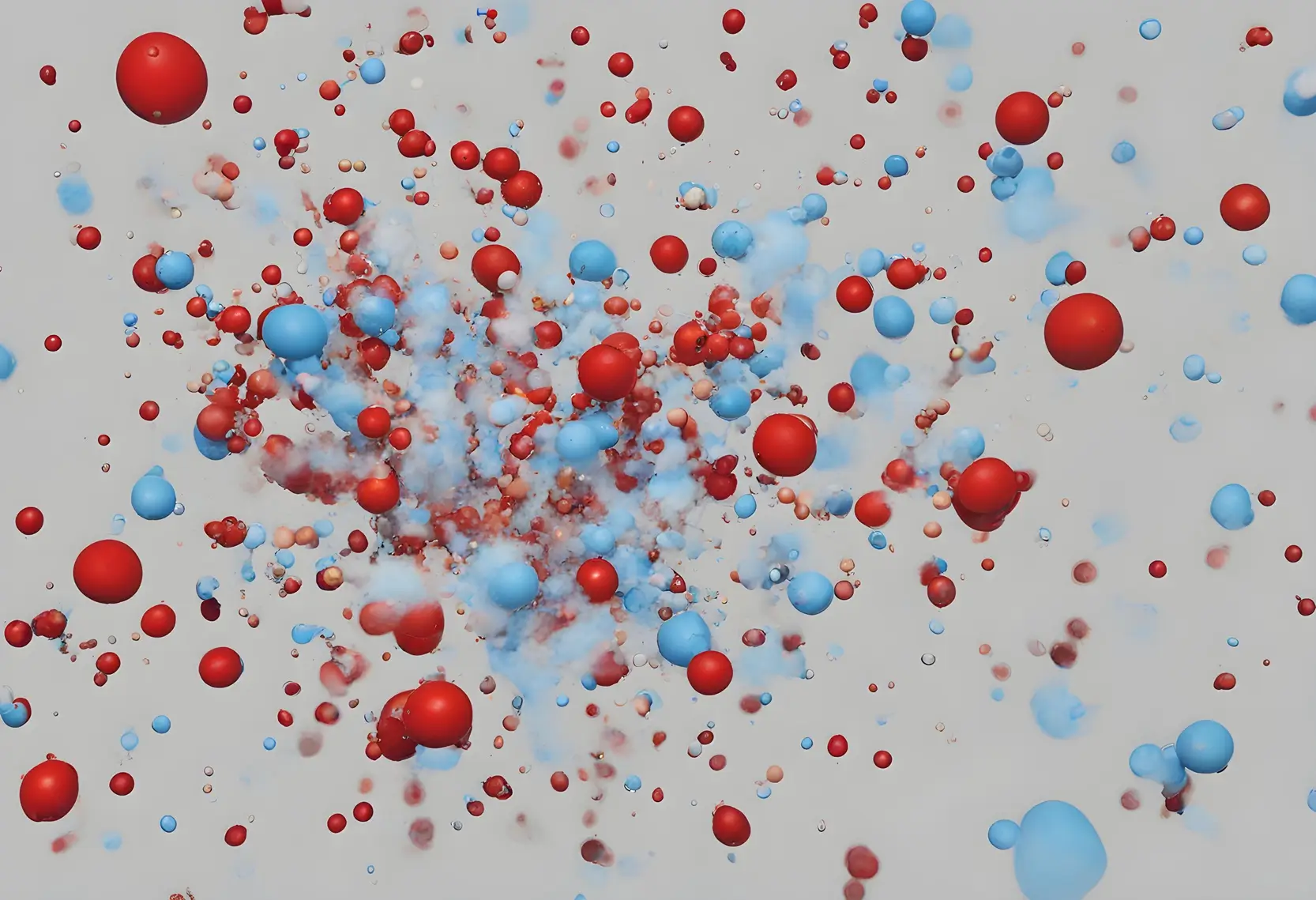

From surface fragments to trench cargo

First, microplastics and fines combine with organics to form marine snow. Then sinking begins across the water column. Typically, speeds reach hundreds to over 1,000 meters per day. Composition and porosity together set the rate. Additionally, biofouling and mineral ballast raise effective density. Consequently, aggregates cross pycnoclines and reorganize under shear. Eventually, they deliver the load onto deep sediments. In the Mariana, hadal sediments show high burdens. Reported values span hundreds to thousands of pieces per liter. Finally, common polymers include PE, PA, and PVC.

Measurement realities

First, the method drives the numbers. Mesh choice strongly shifts counts. Moreover, lab tools limit detection. Typically, FTIR resolves particles above about twenty micrometers. Meanwhile, Raman mapping can reach near one micrometer. However, nanoplastics remain hard to quantify at scale. In addition, in situ high-pressure imaging is still maturing. Therefore, compare like with like when citing loads.

Trenches, plumes, and gravity currents

Trenches gather particles by shape and density. After disturbances, gravity currents move plumes downslope. Moreover, deep-sea mining trials confirm this pattern. In the near field, plumes carry high suspended loads. Consequently, dense currents travel hundreds of meters downslope. In turn, flow velocity and bottom slope set the reach. Likewise, plants show gravity-driven fines with the same behavior. Finally, upset events trigger resuspension that mirrors trench pulses.

What powder engineers can borrow from deep-sea particle dynamics

1) Aggregation controls residence time

First, small particles linger without aggregation. By contrast, marine snow behaves differently. Consequently, flocs change drag and slip. Thus, residence time collapses once aggregates form. In plants, floc strength and porosity shift cyclone cut size. Accordingly, adjust mixing and electrolyte content to tune floc traits.

2) Shape factors magnify wear

Irregular particles deflect in pumps and bends. Consequently, they strike walls at sharp angles. As a result, erosion rises outside design speeds. Similarly, the ocean shows the same bias. Needle-shaped diatom chains seed long aggregates. In turn, those forms change settling and impacting. In plants, track sphericity and angularity with image analysis. Then match the impeller, liner, and velocity windows to shape data.

3) Density contrast sets pathways

First, ballasting raises effective density, so sinking accelerates. Likewise, the same rule governs dense phase transfer. Moreover, air velocity, particle density, and loading determine flow mode. Therefore, tune density contrasts with benign ballast or coatings. Next, validate settings with settling columns and pressure measurements. Finally, capture fines before they enter fast channels.

4) Stratification creates traps and bursts

First, pycnoclines slowly descend, then release pulses. Next, process plants show similar layered flows. Inside ducts, dead zones form while shear layers persist. Therefore, design baffles and diffusers to limit the accumulation of fines. Finally, use sensors to capture bursts rather than the mean.

5) Plumes behave like dense sprays

First, near-field plumes hug the bed. Then they thin and spread along the slope. Next, geometry and thrust together set the footprint. Similarly, the behavior mirrors hopper discharges into the air. Therefore, use near-field shields and low-momentum releases. Finally, reduce shear, and let dilution do the rest.

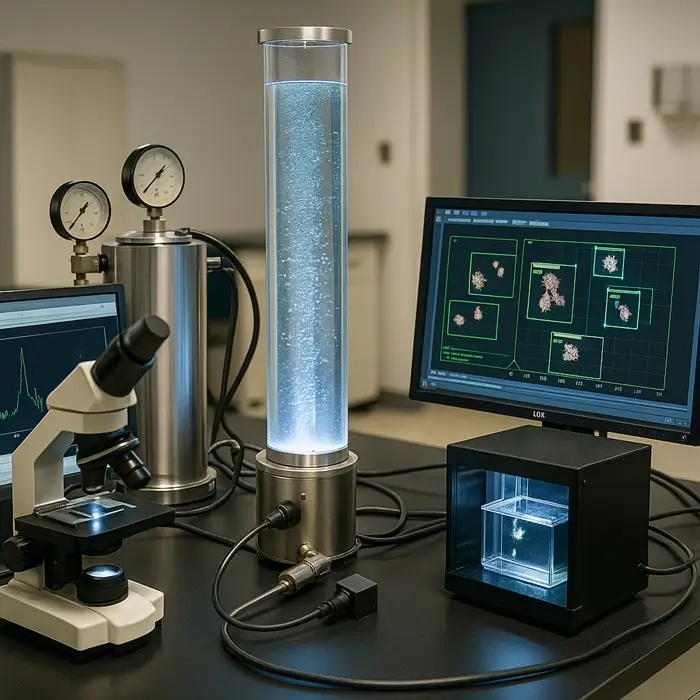

Tooling and analytics to copy

-

Image analytics with AI. Object detection tracks floc growth and shape. It beats manual reads during transients. Apply similar tools to plant cameras. Flag abnormal PSD or stringers in real time.

-

Pressure-aware material tests. High pressure shifts polymer behavior. Ocean data remind us to test beyond ambient. Use elevated pressure and low temperature where relevant.

-

Method standardization. Field counts vary with method. Lab counts do as well. Lock sampling meshes and spectroscopy settings.

Open questions to ask

-

How does floc porosity change under shear?

Porosity sets drag and settling speed. Measure with imaging and settling columns. -

Which shape factors drive pump wear most?

Track sphericity and angularity. Pair image analysis with erosion coupons. -

What density contrast triggers fast sinks?

Adjust mineral ballast and coatings. Measure terminal velocities in columns. -

Where do stratified layers hold fines?

Layers create traps and bursts. Map with inline turbidity and velocity probes. -

How do nanoplastics aggregate at plant shear rates?

Aggregation shifts PSD and capture. Use controlled mixing, DLS, and microscopy. -

Which surfaces curb near-field plume spread?

Lower jet momentum helps. Compare liners and chute geometry in a scaled test. -

What sampling method preserves trend fidelity?

Mesh and optics change counts. Lock protocols and audit inter-site variance.

Practical checklist for plants

-

Map shape, density, and surface energy together.

-

Promote or prevent flocculation on purpose.

-

Control near-field jet momentum at discharges.

-

Stay in velocity windows that limit erosion.

-

Instrument for bursts, not only averages.

-

Standardize sampling and analytics across sites.