Featured articles

Powdertechnology.info insight of the week

Laser Diffraction at elevated temperatures

Laser Diffraction at elevated temperatures

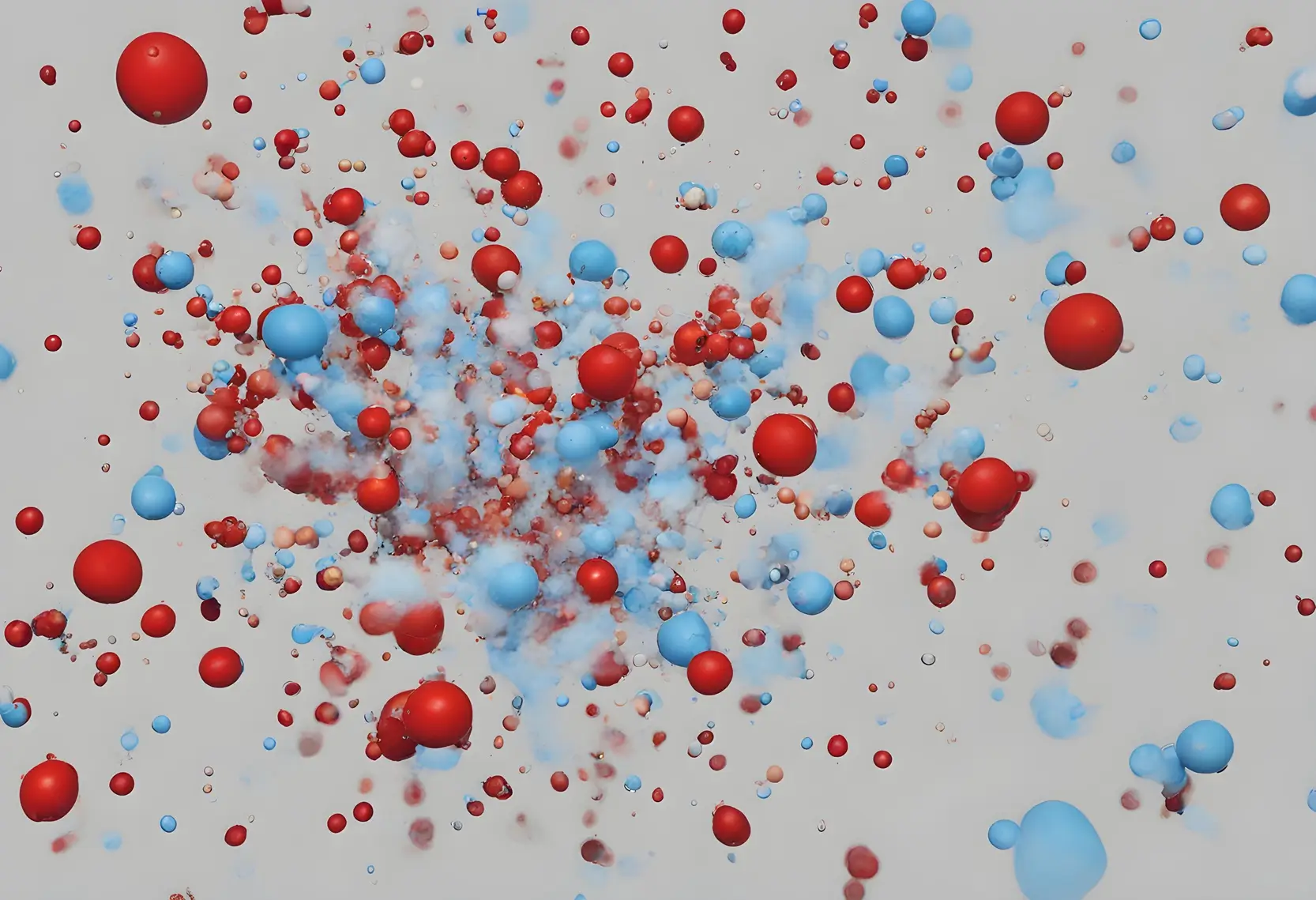

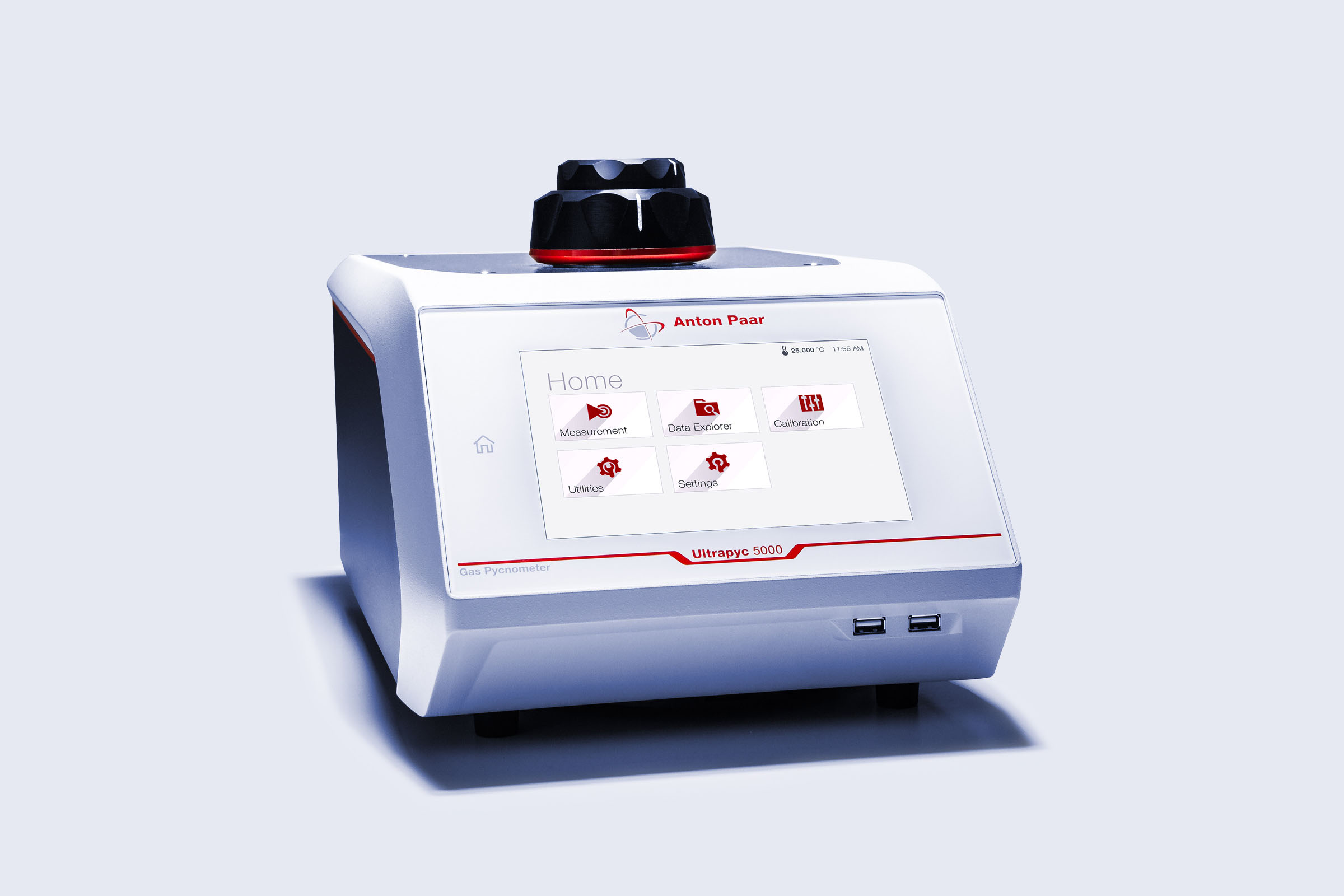

A special setup is developed to investigate samples at higher temperatures up to 85 °C. The setup is made by placing the 1L dispersion tank with reinforced PVC tubes, which could handle higher temperatures. These tubes are thicker than the standard tubing and have gold-painted screws that are used to attach them to the instrument (measurement cell). In front of the tank, a tripod holding a temperature sensor and a heating element (350W) are placed in the liquid in the dispersion unit. Both the sensor and heating element are controlled by a temperature controller. The measurement cell is isolated with Styrofoam and the tank’s surface (where the liquid is visible) is also packed with Styrofoam, which is tailored in both cases. When performing the measurements, approx. 1 liter of the dispersant is placed into the tank (minimum level of the heating element should be achieved). This is stirred and pumped through the system as the background is checked. Then the dispersant is heated by turning the heating on with the temperature regulator. The system is stabilized by letting it heat for half an hour after reaching the required temperature.The background is measured. The sample is heated to the required temperature with a stirring/heating plate. The sample is then homogenized with a top stirrer and an aliquot of the sample is transferred into the 1 liter tank. When the required obscuration is obtained, the sample is measured and the particle size distribution at a higher temperature is obtained. Our conclusion of the week:

Powders dispersed in liquids can behave differently at process temperature and room temperature and could have different particle size distributions. Therefore it might be necessary to know the particle size distribution at higher temperatures.

Our setup, with reinforced PVC and precise temperature control up to 85 °C, enables accurate laser diffraction measurements, unveiling the dynamic particle size distribution of powders in a liquid at elevated temperatures.

Previous weekly insights

what’s trending

Monthly Top Tips

Our videos

Top Pick Articles

editor’s picks

Prime Archive content, selected by our editors.

Partner content

popular news & articles

News and articles in your inbox

Sign up and receive PowderTechnology.info news, articles, and content from our partners in a quick and easy monthly newsletter.

Popular this month

Events

Delft Solids Solutions presents a comprehensive 2-day Particle Characterization course, intricately linked with a 1-day Porosity and Surface Area Characterization program. Designed for industries dealing with diverse materials, the course explores fundamental principles, definitions, and techniques for particle size and shape characterization. Key topics include sampling, sieving, sedimentation, microscopy, and quality control, with practical demonstrations reinforcing theoretical knowledge in the well-equipped laboratory. Scheduled for November 26-27, 2024, in Wateringen, The Netherlands, the course offers participants a profound understanding of particle characterization techniques, enabling them to interpret results and ensure measurement reliability. Upon completion, a certificate of participation is awarded. For inquiries or registration, contact Delft Solids Solutions at +31 174 271 460 or info@solids-solutions.com.