Particle Size Analysis in drug development

Small Matters: Particle Size Analysis in drug development Laser Diffraction We are always willing to help This is feasible due to the broad array of instruments and specially designed and built setups, accessories, and sample holders and access to a modern workshop enabling the design of additional accessories. Contact Delft Solids Solutions via phone +31 174 271 460 or email info@solids-solutions.com

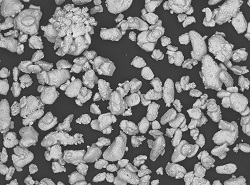

Innovative drug development in the 21st century is a long, laborious process. From concept to counter, many complex steps are involved in identifying, developing and integrating a new active pharmaceutical ingredient (API) into a suitable dosage form (mixture with excipients). This must then be thoroughly tested for patient usage. Certain physical characteristics of APIs determine their applicable properties. Particle size is arguably the most important of these variables. Changes in particle size might alter the correlated properties, i.e. shape, surface area, and porosity. This, in turn, can affect bulk properties, product performance, processability, stability, and appearance of the end product. The APIs being developed are increasingly more intricate, and smaller particle sizes are typically required in the pharmaceutical industry. Therefore monitoring particle size is paramount to the entire development and manufacturing process. Particle shape and particle size distribution, and particle surface characteristics also influence the performance and appropriateness of a drug formulation. The link between particle size and product performance is well documented with regard to dissolution, absorption rates, and content uniformity. Reducing particle size can aid in the process of hygroscopicity. Particle size analysis is an integral component of the effort to formulate and manufacture many pharmaceutical dosage forms.

Changes in particle size might alter the correlated properties, i.e. shape, surface area, and porosity. This, in turn, can affect bulk properties, product performance, processability, stability, and appearance of the end product. The APIs being developed are increasingly more intricate, and smaller particle sizes are typically required in the pharmaceutical industry. Therefore monitoring particle size is paramount to the entire development and manufacturing process. Particle shape and particle size distribution, and particle surface characteristics also influence the performance and appropriateness of a drug formulation. The link between particle size and product performance is well documented with regard to dissolution, absorption rates, and content uniformity. Reducing particle size can aid in the process of hygroscopicity. Particle size analysis is an integral component of the effort to formulate and manufacture many pharmaceutical dosage forms.Delft Solids solutions offers a range of analytical instruments providing both insights and support for Particle Size Analysis in drug development.

The particle size distribution of powders is important to describe the effectiveness of physical end chemical processes and the quality of semi-finished products and final products. Modern techniques cover a size range from nanometers up to millimeters.

Investigations and analysis are performed in close consultation with the customer and – as far as possible – executed under conditions that closely match the targeted application of the product or actual problem.