The ever-evolving digital landscape has catalyzed transformative growth across various industries. Over the last few decades, the transition from Web 1.0 to Web 2.0, with the anticipation of Web 3.0, has led to numerous advancements that have revolutionized the way we connect, create, design, utilize, and consume information. Just as powder technology has experienced significant growth and innovation over the past 30 years, the World Wide Web (WWW) has followed a similar trajectory of continuous innovation and design. AI in Powder Technology opens the door to new revenues of exploration and industry growth.

The Evolution of the Web

Web 1.0, often called the “read-only” web, laid the foundation for the digital revolution, enabling global access to information. Web 2.0 marked a pivotal shift, turning the internet into an interactive platform, allowing users not only to consume but also to contribute, collaborate, and create content.

Impact on Powder Technology

Considering powder technology, these shifts accelerated the development of new production techniques like sintering, hot isostatic pressing, atomization, and gas atomization. They resulted in a wealth of digital content in the form of research papers and projects, inspiring researchers and enhancing the properties and functionalities of powder-based materials.

The Influence of the Web on Industries

The evolution and widespread adoption of the internet, from Web 1.0 to Web 2.0, have profoundly impacted various industries, affecting supply chains, manufacturing, marketing, and customer interaction. These phases have facilitated global industries in promoting their products, and services, and fostering more significant consumer interaction and feedback.

Web 1’s Impact on Manufacturing

In the Web 1.0 era (around 1993), manufacturers gained access to a wealth of information related to powder technology and other sciences. Online platforms provided access to research papers, industry reports, and technical specifications, fostering knowledge sharing and keeping manufacturers updated with the latest developments.

Additionally, the widespread adoption of email improved communication among manufacturers, suppliers, customers, and stakeholders, streamlining document exchange and enhancing manufacturing processes. The emergence of online directories and marketplaces connected powder technology manufacturers with potential customers, expanding their reach and uncovering new business opportunities.

Web 2’s Impact on Manufacturing

Web 2.0, emerging in the early 2000s, revolutionized the manufacturing industry. It facilitated collaborative problem-solving and idea-sharing through social media, online communities, and collaborative tools. Manufacturers in the powder technology sector engaged in fruitful collaborations, enhanced supply chain management with real-time data sharing, and improved customer engagement through interactive websites and online forums.

The growth of e-commerce empowered manufacturers with direct sales to consumers, bypassing traditional distribution channels, and resulting in more control over pricing and market reach.

The Significance of Web 2.0

Both Web 1.0 and Web 2.0 have transformed the manufacturing sector, revolutionizing information access, communication, collaboration, supply chain management, customer engagement, sales, and data collection, driving research, development, innovation, and business opportunities.

Bandwidth and Information Sharing

The impact of Web 2.0 on manufacturing extended beyond content and interactivity, as it brought advancements in internet speeds and bandwidth. The shift from dial-up connections to high-speed broadband connections, such as DSL and cable internet, improved user experiences, enabling the emergence of Web 2.0 technologies.

It’s crucial to recognize that this shift wasn’t solely due to increased speed but also resulted from advances in web development technologies, the rise of social media, and changes in user behavior. These developments have significantly benefited the manufacturing industries, enhancing research access, equipment acquisition, advertising, supply chain networks, monitoring, safety practices, and more.

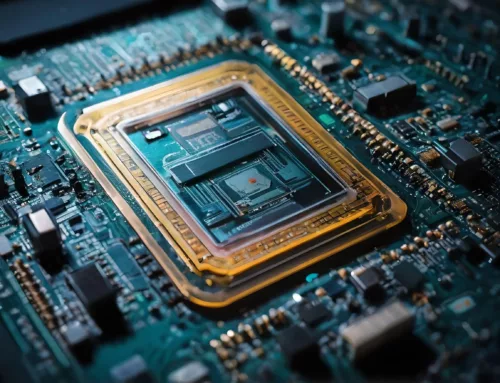

The Unfolding of Web 3.0: AI and powder technology

Web 3.0 represents the next phase, driven by artificial intelligence (AI), characterized by its semantic, decentralized, and blockchain-based infrastructure. This phase holds the potential to impact the manufacturing industry even more profoundly than Web 1.0 and 2.0.

Through Web 3.0 technologies, manufacturing processes could undergo revolutionary changes. The Semantic Web, with standardized formats like RDF and OWL, enhances data interpretation for machines, enabling data integration, interoperability, and the development of intelligent applications to improve manufacturing efficiency.

The decentralized design of Web 3.0 enhances supply chain security by utilizing blockchain technology, ensuring secure traceability of materials and products from source to user. This capability extends to efficient recycling processes, fostering sustainability.

AI in Powder Technology: Enhancing Efficiency and Security

Web 3.0’s integration with AI can further drive automation and robotics, empowering intelligent machines to undertake complex tasks and optimize production efficiency. Data privacy and ownership are central themes, with AI techniques like federated learning and differential privacy safeguarding sensitive data while enabling insights into customer behavior and market trends.

The integration of Web 3.0, AI, and blockchain in the powder technology industry positions it for greater efficiency, traceability, and security. Manufacturers embracing these technologies gain access to decentralized collaboration networks, streamlined storage and transportation, cost reductions, enhanced security, and optimized supply chain management.

This transformative integration prepares the powder technology industry to meet the increasing demands for efficiency, quality, environmental sustainability, and product longevity in the years to come.