Why control banding for powders matters now

Most powder plants operate in a permanent gray zone. Some materials arrive with full toxicology, occupational exposure limits and robust documentation. Others turn up with a thin safety data sheet, a nuisance dust warning and little context about real exposure risks. On the shop floor, operators still open bags, connect big bags, sample from chutes and clean spills. Fine particles become airborne whenever these tasks disturb powder surfaces, regardless of how complete the dossier looks.

Control banding for powders is designed for exactly this situation. Instead of demanding a precise exposure limit for every single material and task, it groups combinations of hazard and exposure into bands. Each band maps to a defined level of control, from good general ventilation through local exhaust extraction up to full containment. That shift pulls the conversation away from abstract numbers and into concrete design choices, operating procedures and investment priorities.

How a powder focused control banding scheme works

A practical scheme links three steps: assigning a hazard band, scoring an exposure band and translating the combination into a control band.

Step 1: Assign the hazard band

The starting point is the material itself. You use the strongest information available, such as any existing OEL or OEB value, the hazard statements on the safety data sheet and structural similarity to better studied substances. Frameworks like the NIOSH occupational exposure banding process provide useful starting points for this step.

Strong sensitizers, cobalt compounds and highly potent APIs naturally fall into higher hazard bands. Inert mineral fillers with nuisance dust classifications fall into lower bands. Many functional additives and organic powders land in the middle, where uncertainty is greatest and structure helps the most.

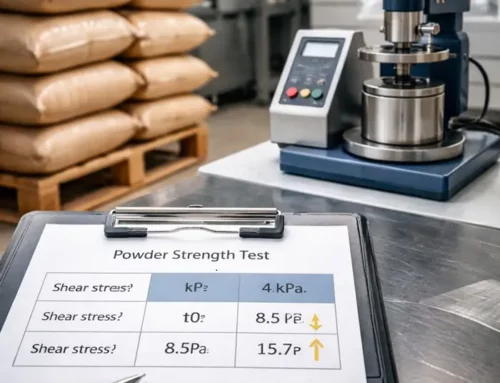

Step 2: Score the exposure band

Next you examine how the specific task creates exposure. This is where powder behavior becomes visible. You consider dustiness, the quantity handled, the duration and frequency of the task and how close the operator stands to the emission point. Repeatedly cutting dusty 25 kilogram bags at chest height produces a high exposure band. Monitoring a sealed loss in weight feeder produces a low exposure band. Walking past a closed screw conveyor during normal operation is also low exposure. The powder is the same in each case, but the way you handle it changes the exposure band completely.

Step 3: Link the result to a control band

Finally, you combine the hazard band and exposure band into a control band. This structure is similar to the HSE COSHH Essentials control banding approach widely used for chemicals and dusts. Lower control bands may only require good general ventilation, basic housekeeping and clear work instructions. Medium bands typically demand local exhaust ventilation at the emission point, together with work practices that keep operators out of the main plume. The highest bands expect enclosure and engineered barriers, such as glove ports, liner clamping, contained discharge and defined leak management. The key is discipline: every task that lands in the same band receives at least the same minimum level of control.

One powder, three tasks on one line

Consider a single powder blend used on one production line. Operators discharge big bags into a hopper; the blend moves through a closed screw conveyor, and later operators take manual samples from an open chute, all of which sit within broader material handling and storage systems. The hazard band is identical for all three tasks, because the material does not change.

The exposure bands are very different. Big bag discharge involves high dustiness, large quantities and close operator presence, which leads to a high exposure band. The closed screw conveyor remains sealed during normal operation, keeping exposure low. Sampling at the open chute involves small quantities per grab, but it happens frequently, and the operator’s head is close to the stream, resulting in a medium exposure band.

Control banding for powders makes these differences explicit. The big bag station may need full enclosure with extraction and liner clamping. The screw conveyor may only need periodic verification that it remains closed and leak-tight. The sampling point may need a dedicated capture hood, a fixed sampling position and a standardized method. The internal discussion shifts from “is this powder dangerous?” to “which task drives risk and deserves investment first,” which is a much more useful question.

Where control banding fits in your risk strategy

Control banding for powders is a screening and prioritization tool, not a replacement for detailed risk assessments or exposure measurements. For a broader introduction, the CCOHS overview of control banding gives a clear, non-technical summary. Complex carcinogens, reprotoxic substances and powders with very low existing OELs still require specialist input and targeted occupational hygiene campaigns. Explosion-dominated scenarios, where electrostatics, confinement and ignition sources set the risk, also need separate analysis and design rules.

Even in those situations, a clear control banding rationale adds value. It documents why specific controls apply to particular tasks, and it helps explain decisions to auditors, authorities and operators. It also creates a stable framework for integrating new products and new tasks over time.

A practical starting point is small and targeted. Choose one line or one product family. List all powder handling tasks in that scope. Assign hazard bands to the powders, score exposure bands for each task, and agree on the resulting control bands in a cross-functional group that includes operations, engineering and HSE. Mark the tasks that still need measurements or deeper study. You will not get every decision perfect on day one. You will, however, replace case-by-case improvisation with a visible, consistent logic for exposure control. For many plants, that is the real gain: control banding for powders turns incomplete data into action instead of delay.