Analytical Techniques and methods

Analytical techniques are vital for understanding and optimizing the properties of powders and materials. From particle size analysis and flowability testing to porosity and surface area evaluation, these methods provide essential insights into material behavior. Advanced tools like SEM imaging, BET analysis, and zeta potential measurement ensure precision and drive quality across applications.

Page menu

Featured Analytical Techniques and methods Articles

News And Articles In Your Inbox

Sign up and receive PowderTechnology.info news, articles, and content from our partners in a quick and easy monthly newsletter.

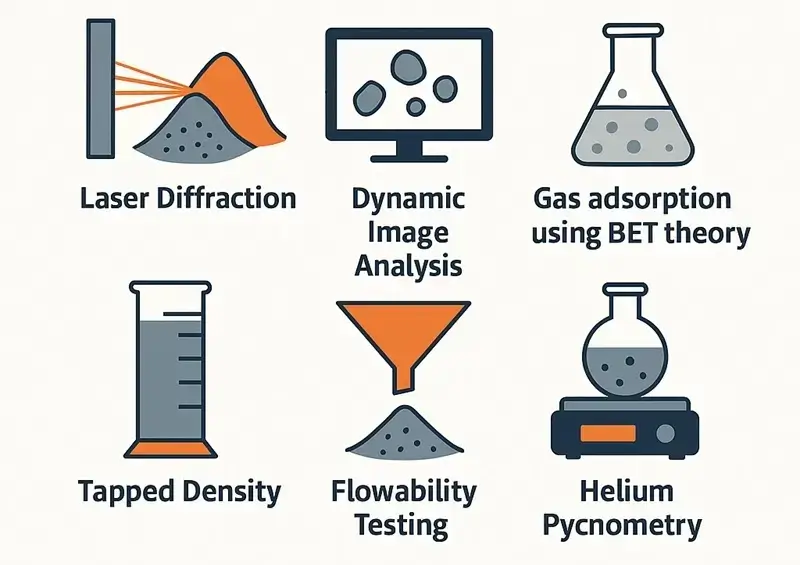

Analytical Techniques and methods: Particle Size Analysis

Featured Particle Size Analysis Articles

More Particle Size Analysis Articles

More Particle Size Analysis Articles

Analytical Techniques and methods: Flowability Testing

Flowability testing is essential for understanding powders’ behaviour during handling, storage, and processing. By measuring properties like flow rate, angle of repose, and cohesive strength, these tests help predict performance and identify potential issues like clogging or segregation. Explore advanced tools and techniques that ensure efficient material flow, optimize processes, and maintain product quality across industries.

More Flowability Testing Articles

Featured Flowability Testing Articles

More Flowability Testing Articles

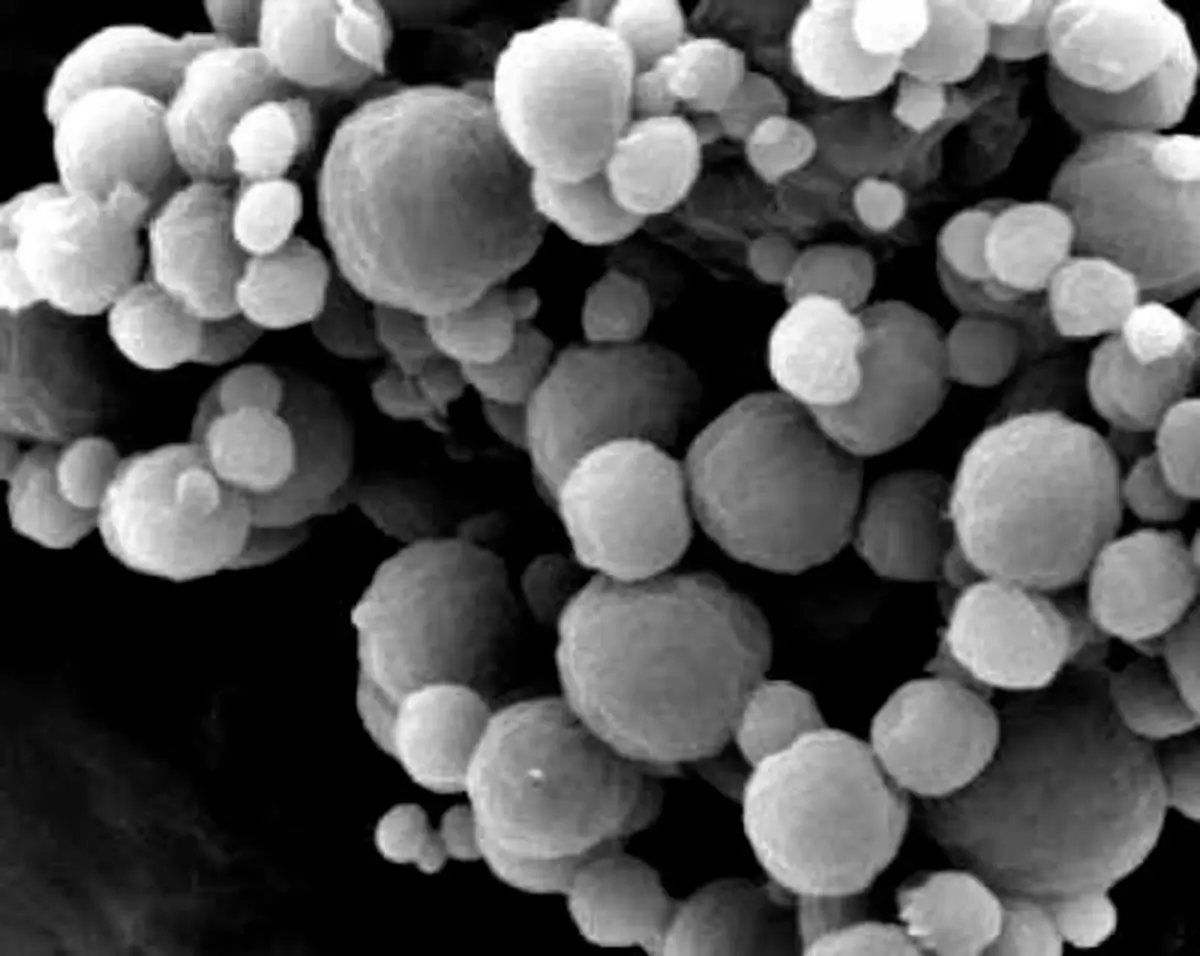

Analytical Techniques and methods: Microscopy Tools

Microscopy tools provide a window into the microscopic world of powders and materials, revealing critical details about particle shape, size, and surface properties. From high-resolution imaging with SEM to advanced techniques like confocal and atomic force microscopy, these tools deliver precise insights into material characteristics. Explore how microscopy enhances understanding, quality control, and innovation across industries.

Featured Microscopy Tools Articles

More Microscopy Tools Articles

More Microscopy Tools Articles

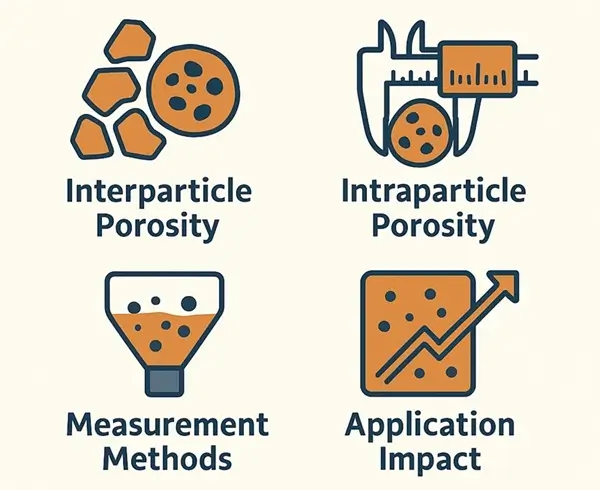

Analytical Techniques and methods: Porosity and Surface Area Testing

More Porosity and Surface Area Testing Articles

Featured Porosity and Surface Area Testing Articles

More Porosity and Surface Area Testing Articles

Analytical Techniques and methods: Moisture and Thermal Analysis

Moisture and thermal analysis are essential for evaluating the behavior of materials under varying conditions. These techniques provide insights into moisture content, thermal stability, and decomposition processes, critical for optimizing production, storage, and application. From thermogravimetric analysis (TGA) to moisture content testing, these methods ensure material quality and performance across industries.

More Moisture and Thermal Analysis Articles

Featured Moisture and Thermal Analysis Articles

More Moisture and Thermal Analysis Articles

Analytical Techniques and methods: Chemical Composition Analysis

Chemical composition analysis provides critical insights into the elemental and molecular makeup of materials. By employing techniques such as X-ray diffraction (XRD), X-ray fluorescence (XRF), and Fourier-transform infrared spectroscopy (FTIR), these methods identify material properties, impurities, and chemical stability. Understanding chemical composition ensures product quality, compliance with standards, and optimization across various industrial applications.

More Chemical Composition Analysis Articles

Featured Chemical Composition Analysis Articles

More Chemical Composition Analysis Articles

Analytical Techniques and methods: Bulk Solids Testing

Bulk solids testing evaluates the unique properties of powders and granular materials to optimize their handling, storage, and processing. Techniques like rotating drum analyzers, shear cells, and uniaxial compression testing reveal insights into flow dynamics, shear strength, and compressibility. These methods ensure efficiency and reliability across industries, supporting consistent performance in diverse applications.