Inert particle size assessment: handling in glovebox and dispersion in water-free organic “solvent”

Some powders are sensitive to air (oxygen) or water (humid air). Also for these types of samples, it is interesting to know the particle size of the powder produced. With a lot of particle-size instruments, it is difficult to measure these types of samples, as there is no option to measure inert. Therefore at Delft Solids Solutions, we have developed a method to measure the particle size distribution at an inert way so that air-sensitive materials can still be measured.

First, the samples should be made and stored inert before the particle size analysis. There are special screw cap septum vial available so that there is no transfer between air inside and outside the vial. If the material is placed in a dry solvent (like special water-free heptane or hexane or liquid used in the production process) into the vial, this can be flushed with nitrogen gas and sealed with the screw cap. This will then be stored in a special glovebox until the measurements will be executed. The glove box is a cabinet containing nitrogen gas, so that the material will for sure not be in contact (humid) air.

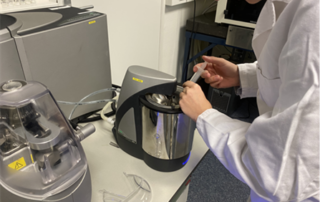

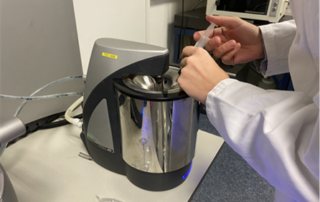

The dry solvent will also be used during the particle size measurements with laser diffraction. First, the dispersion unit and measurement cell will be flushed with the dry solvent at least four times, to ensure that all water is removed. Then the dispersion unit will be filled with the dry solvent so that the sample can be transferred into the unit. With a syringe and needle with a sufficiently large opening, the material will be transferred to the dispersion unit. Before the sample transfer, the syringe is rinsed with the dry solvent and some dry solvent will also be put into the syringe before taking the sample.

The needle is then carefully put into the septum and the sample is dispersed in the vial. After homogenizing the vial, some sample is taken from the vial into the syringe and this is removed from the septum. The syringe with sample material is placed into the solvent in the dispersion unit and the syringe is emptied in the solvent so that there is no contact with the air during emptying. The sample is then directly measured to make sure a good measurement is obtained as it might be possible that in time the material might still change some bit. During several investigations, we have seen this is a suitable method to measure the particle size distribution of air-sensitive materials and we will always continue to investigate more options for measuring the particle size of air-sensitive materials.

Our conclusion of the week:

Even if it is wet outside – there are always possibilities to measure materials dry!