Moisture Content Analysis in Powder Samples an introduction

People encounter moisture daily. This includes humidity in the air, damp clothes, and food moisture. High humidity levels, like those in Dubai or the Asian tropics, affect comfort and health. People often rely on dehumidifiers or multiple air conditioners (ACs).

Moisture refers to the presence of water in tiny droplets or vapor. It forms through evaporation, where water turns from liquid to gas. It also forms through condensation, where water vapor cools into liquid droplets. For example, hot 45-degree air meets the cool surface of a window. This occurs in a villa with the AC set at 19 degrees Celsius.

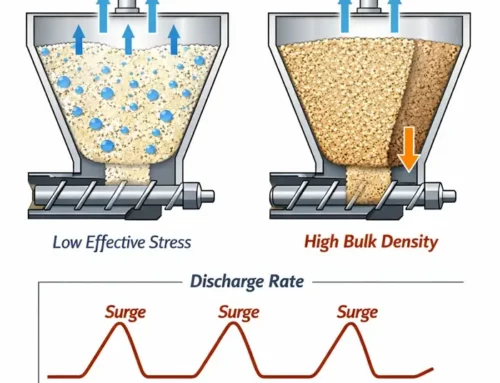

Moisture is essential for life. It provides hydration for biological processes in plants, animals, and humans. In powder technology, moisture content affects the flow, compaction, and stability of powders. Adequate moisture prevents powders from becoming too dry and dusty. This allows for easier handling and processing.

However, excessive moisture can cause clumping and reduce shelf life. This compromises the quality and usability of powders. Balancing moisture levels optimizes the performance and longevity of powders in various industrial applications.

Though we may not always think about it, moisture influences our daily routines. It also affects industrial processes alike. That’s why moisture content analysis is so important.

Understanding Moisture Content

Moisture content refers to the amount of water present in a material, usually expressed as a percentage of the material’s total weight. In powders, moisture can exist in various forms, such as free water on the surface, as water bound within the particles, or as chemically bound water. Accurately determining the moisture content is important for controlling product quality, optimizing storage conditions, and ensuring smooth processing.

In powder processes, managing moisture content is essential in preventing bacterial growth, in addition to ensuring flowability, stability, reactivity, and shelf life. The critical factor for inhibiting bacterial growth is water activity (aw), which measures the free moisture available for microbial proliferation, ranging from 0 (completely dry) to 1 (pure water). Bacterial growth is significantly inhibited at water

Moisture Content and regulations

Bacteria generally cannot survive at water activities below 0.6 aw, although some molds and yeasts can grow at slightly higher levels, typically around 0.7 aw. While the exact minimum moisture content depends on the composition of the powder, keeping water activity low reliably ensures product safety. The 0.6 aw threshold, often referred to as the safe moisture level or critical moisture content, is vital for maintaining the overall integrity of powdered products.

Regulatory bodies, such as the U.S. Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA), enforce strict guidelines on moisture levels. In Asia, countries like Japan and China regulate moisture content through agencies such as Japan’s Ministry of Health, Labor and Welfare (MHLW) and China’s National Health Commission (NHC). The International Organization for Standardization

(ISO) also sets comprehensive standards to ensure acceptable moisture safety levels worldwide.

Regulatory bodies set specific standards for moisture content. For example, the FDA Food Code and various compliance policy guides outline these standards for food safety, while ISO 21807:2004 provides guidelines for determining water activity in food and animal feedstuffs. Adhering to these standards minimizes the risk of bacterial contamination and other moisture-related issues in powders, ensuring product safety and extending shelf life on a global scale. Moisture content significantly influences the properties and performance of powder materials, impacting their stability, flowability, reactivity, and shelf life. Accurately determining moisture content is critical in industries such as pharmaceuticals, food processing, agriculture, and materials science. It ensures quality control, optimizes processing conditions, and ensures compliance with industry standards.

Gravimetric Method

Currently, the gravimetric method stands out as one of the most widely used techniques for determining moisture content. Technicians weigh test samples before and after drying, and the difference in weight represents the amount of moisture lost. The procedure typically involves placing the sample in a drying oven set between 105°C and 110°C for a pre-defined period. After drying, the technician cools the sample in a desiccator to prevent moisture absorption from the environment and then reweighs it. Industries commonly use this method in the food and pharmaceutical sectors due to its simplicity and accuracy. However, its simplicity has a drawback; it is quite time-consuming and unsuitable for materials sensitive to heat, as high temperatures can cause decomposition or chemical changes to the sample. A similar method, Loss on Drying (LOD), also heats the sample to remove moisture. Technicians weigh the sample before and after drying.

This method measures the total amount of volatile substances, including moisture, lost upon heating. The food and pharmaceutical industries widely use it because of its simplicity and minimal equipment requirements. However, this method does not always distinguish between water and other volatile substances, which can lead to inaccuracies.

Like the previous methods, thermogravimetric analysis uses heat in a controlled environment to measure a sample’s weight change. This analysis provides detailed information about the sample’s thermal stability and moisture content. The weight loss at different temperatures indicates the presence of moisture and other volatile substances, and industries use it in materials science and pharmaceuticals. Thermogravimetric analysis offers comprehensive data on weight changes and decomposition temperatures, but it requires specialized equipment and interpretation of more complex data.

Karl Fischer Titration

The Karl Fischer titration method measures moisture content through a chemical reaction with a water-reacting reagent. This method is highly accurate and commonly used in pharmaceuticals and industries requiring precise moisture determination.

The process begins by dissolving or dispersing the powder sample in a solvent. The Karl Fischer reagent, containing iodine, sulfur dioxide, and methanol, is then added. The water content is determined by the amount of reagent consumed. This technique is highly specific to water and provides accurate results, even for low-moisture samples. However, it requires careful handling of chemicals and precise calibration of the titration system for reliable results.

Infrared (IR) Spectroscopy

Like Karl Fischer titration, Infrared spectroscopy also requires careful calibration, but it may be less accurate due to interference from other components in the sample that absorb infrared light. This method measures how much infrared light the sample absorbs, correlating with its moisture content. In this technique, operators expose the powder sample to infrared light and measure the absorption at specific wavelengths corresponding to water. They calculate the moisture content based on the absorption intensity. Industries use infrared spectroscopy for non-destructive, fast moisture analysis. It can continuously monitor water content in milk powder during production, soil moisture levels in agricultural fields, reaction mixtures during chemical synthesis, and atmospheric conditions.

Dynamic Vapor Sorption

Within controlled environments like greenhouses, dynamic vapor sorption (DVS) stands out among several other methods not covered. DVS primarily serves the pharmaceutical and food industries to study hygroscopicity and moisture-related properties. It provides detailed information on moisture sorption kinetics and equilibria. Unlike the previously mentioned methods that use light or heat, DVS measures the sample’s moisture uptake and loss as humidity levels vary.

In a chamber with controlled humidity, operators measure the weight change of a sample as humidity changes, creating a profile of moisture sorption and desorption. Although DVS provides accurate data, it is a time-consuming method that requires precise control over humidity and temperature.

Applications Across Industries

With pharmaceuticals, moisture content analysis ensures drug formulations remain stable and effective, prevents degradation, and optimizes shelf life during storage. Excess moisture can also create unwanted compounds or affect the drug’s dissolution rate and bioavailability. Moisture content, in the food industry, influences texture, taste, and product shelf life, making it essential for quality control and regulatory compliance. In agriculture, moisture content affects the quality and storage of products, helping to prevent spoilage and loss. In materials science, moisture content significantly influences the processing and performance of various materials, particularly ceramics, coatings, and composites. Here, moisture can affect the curing process and the mechanical properties of the finished material.