Some powders are sensitive to air (oxygen) or water (humidity), which can significantly affect their properties. For these samples, knowing the particle size of the produced powder is essential for quality control. However, many particle-size instruments struggle to measure these materials effectively. This limitation arises because they lack an inert measurement option, which is crucial for handling sensitive powders.

At Delft Solids Solutions, we have developed an innovative method that measures particle size distribution in an inert environment. This approach allows us to accurately measure air-sensitive materials without compromising their integrity during testing. By ensuring inert conditions, we enable effective analysis that safeguards the samples from environmental influences.

Moreover, this innovative technique provides valuable insights into the characteristics of challenging samples. As a result, we can better understand how different factors impact particle size and behavior. Ultimately, our method enhances the reliability of particle size measurements, paving the way for improved product quality and performance in various applications.

Investigation of Caking in Absorbents

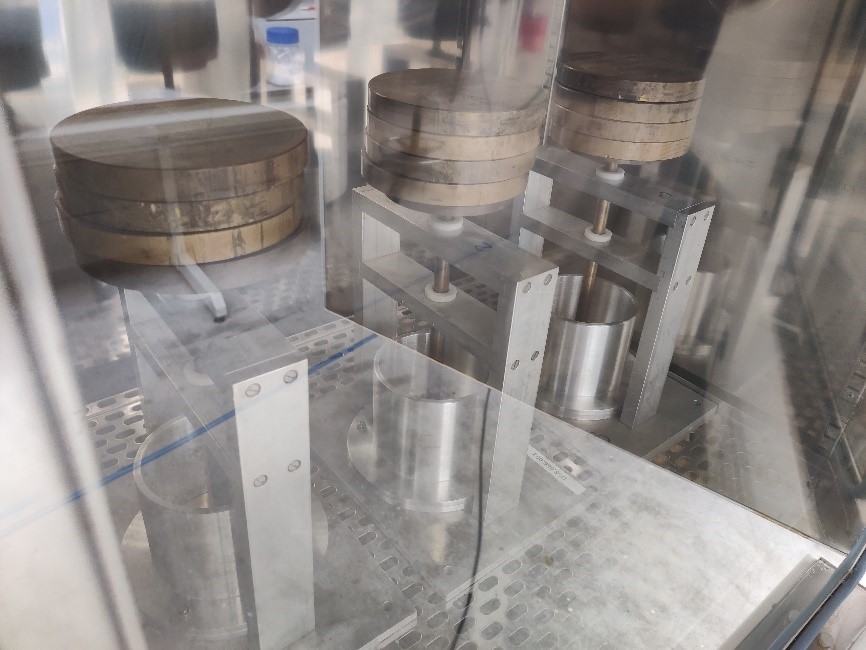

To investigate potential caking and storage issues, we performed uni-axial testing on the absorbent material. The experiments aimed to determine the optimal moisture content to minimize storage problems. We selected three moisture contents for the tests: dry, approximately 30% moisture content, and fully immersed in water.

We placed the absorbent in a uni-axial sample cell with a closed hole at the bottom. We then applied a pressure of 18 kPa to the powder bed and stored the setup for 7 days at 20°C and 65% relative humidity (RH) inside a climate chamber.

After the storage period, we released the pressure and opened the hole in the bottom of the sample cell. The absorbent, composed of spherical particles measuring approximately 1 mm, behaved as anticipated. Upon opening the sample cell, the dry absorbent showed no signs of caking and flowed freely, indicating successful performance under the tested conditions. This result reinforces the effectiveness of the dry absorbent in preventing caking and storage issues.

Behavior of Absorbents Under Different Moisture Conditions

The absorbent with approximately 30% moisture content did not flow upon opening the bottom of the sample cell. Instead, we required about 6 kPa of pressure to initiate flow. This higher pressure requirement stems from liquid bridges forming between the particles, resulting in more cohesive behavior.

In contrast, the absorbent that was fully immersed in water exhibited no caking and flowed immediately after opening the sample cell. The high moisture content caused the absorbent to behave like a liquid, allowing it to flow out of the sample cell with ease. This observation underscores the significant impact of moisture levels on the flowability and handling characteristics of absorbent materials. Understanding these dynamics is crucial for optimizing storage and processing methods.

When storing the absorbent, both dry and fully immersed options offer distinct advantages. Dry absorbent provides convenience; however, obtaining a dry product after processing requires significant energy for drying. This energy-intensive process can drive up operational costs.

In contrast, immersing the absorbent in water may initially seem like the better option due to reduced energy requirements for storage. However, this method presents challenges. The bulk density of the wet absorbent is much higher, necessitating stronger support structures for silos. This increased density can raise construction and maintenance costs. Additionally, the immersion process generates more wastewater, leading to environmental concerns and management challenges.

Our insight of the week:

water can both help and prevent the discharging of your material