Dispersion in chemistry: an introduction

Dispersion plays a decisive role in chemistry and materials science as a pervasive phenomenon. In these scientific disciplines, dispersion is not merely an abstract concept; it is a fundamental property and process that permeates various industrial applications. Specifically, it constitutes a multifaceted phenomenon with far-reaching implications across diverse sectors. These include pharmaceuticals, cosmetics, food production, and more, where the core principles of dispersion are meticulously harnessed to achieve precise outcomes.

Dispersion in chemistry: Dispersions Advantages

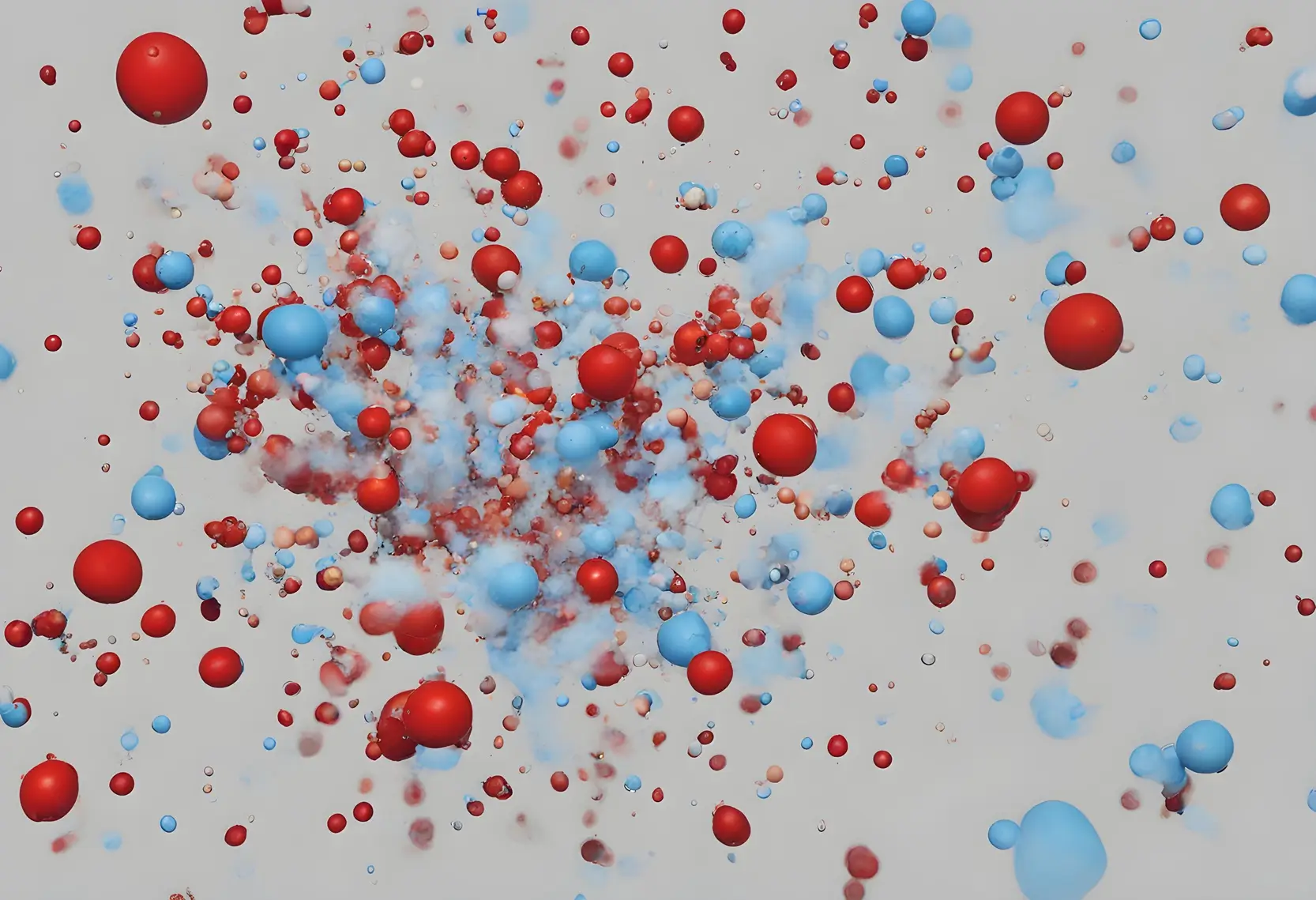

In essence, dispersion can be defined as the uniform distribution of particles within a given medium, typically a liquid or gaseous phase. However, its implications extend far beyond this simple definition. Dispersion exerts a deeper influence on the physical and chemical properties of the materials involved. This influence arises from intricate interactions at the molecular and particle levels, creating a rich landscape of scientific challenges and opportunities.

In the pharmaceutical research and production sectors, dispersion is an indispensable aspect of drug formulation. It dictates the precise arrangement of drug particles within carriers or solvents. Consequently, this arrangement influences factors such as dissolution rates, bioavailability, and, ultimately, therapeutic efficacy. Therefore, a deeper understanding of dispersion in this context is essential for optimizing drug delivery systems and enhancing biological homeostasis.

Similarly, in cosmetics, achieving homogeneous dispersion of active ingredients in creams, lotions, and serums is vital. This uniformity ensures consistent performance and enhances consumer satisfaction.

Dispersion: A Key Principle in Materials Science and Applications

This nuanced control of dispersion ensures that each application provides both aesthetic benefits and the intended functional advantages of the beauty being sold. Additionally, the food industry exemplifies dispersion’s scientific significance. The even distribution of flavoring agents, emulsifiers, and stabilizers within food products combines art and science, ensuring a harmonious and delectable sensory experience. Whether enjoying a chocolate bar, refreshing a carbonated beverage, or savoring a salad dressing, dispersion plays a vital role in enhancing the culinary world’s sensory delights.

Moreover, dispersion extends its influence into materials science and engineering. It is crucial in developing advanced materials, where the precise distribution of particles within matrices is guided by scientific principles. This control results in materials with enhanced mechanical properties, electrical conductivity, and overall performance. Consequently, these advancements shape innovations in diverse industries, including aerospace, automotive, and electronics.

Chemical Reactions and Particle Characteristics

Dispersion forces in chemistry

Beyond its apparent role in simply blending substances, dispersion is intrinsically linked to the intricate science of particle interactions. One of the fundamental forces governing dispersion is the Van der Waals force, specifically the dispersion forces. These forces arise from transient fluctuations in electron distribution, which create momentary dipoles in particles.

The strength of these dispersion forces is directly related to particle size and shape. Larger and more elongated particles exhibit stronger dispersion forces. Additionally, electrostatic interactions play a pivotal role in particle dispersion. Particles can carry electric charges, either positive or negative, depending on their composition.

The Role of Electrostatic Charges in Particle Dispersion

These charges significantly influence how particles disperse and interact. Positively charged particles may repel each other, hindering dispersion unless counterbalanced by other forces. In contrast, negatively charged particles can attract positively charged ones, leading to a more uniform dispersion. This phenomenon is especially relevant in controlled colloidal systems where electrostatic effects can be precisely adjusted to achieve stable dispersions. Brownian motion, resulting from thermal energy, also contributes to particle dispersion. It induces a perpetual commotion of particle movement, collision, and scattering. Smaller particles, endowed with higher Brownian motion, disperse more efficiently and uniformly, encouraging increased interaction with their surroundings.

Surface properties such as polarity and roughness are integral aspects of particle characteristics. Polar particles exhibit distinct interactions with polar solvents when compared to their nonpolar counterparts. The surface area-to-volume ratio is a crucial factor, with smaller particles boasting a larger surface area relative to their volume. This characteristic enables them to engage more extensively with the surrounding medium because maintaining a harmonious balance between particle charge and mass is essential for dispersion stability. An excess charge could lead to particle aggregation, while an insufficient charge could result in inadequate dispersion. These chemical reactions and forces supporting dispersion are indispensable in harnessing its full potential across various industries.

With pharmaceuticals, the precise dispersion of drug particles within a solvent is instrumental in influencing bioavailability and efficacy. In cosmetics, achieving the uniform dispersion of pigments impacts the final color and texture of products. Meanwhile, in the production of food, dispersion influences the texture and taste of an array of products.

Dispersion in chemistry Challenges

As mentioned, dispersion is a fundamental process across diverse industries and unfolds as a nuanced chemical ballet influenced by a multitude of factors and forces. These intricate interactions offer meticulous control and uniformity, yet simultaneously present a series of complex challenges that demand a deep comprehension and precise management.

Agglomeration, a persistent challenge in dispersion, stems from the intricate interplay of attractive and repulsive forces governing the behavior of particles. The prevailing influence of Van der Waals forces, orchestrating temporary electron distribution fluctuations, often sets the stage for this tug-of-war. Electrostatic interactions further complicate matters, either aggravating or ameliorating agglomeration, contingent on the charges carried by the particles involved. Steric hindrance, arising from the spatial arrangement of particles and molecules, also plays a pivotal role, either hindering or promoting dispersion. Countering agglomeration hinges significantly on the selection of dispersants capable of achieving the delicate equilibrium of repulsion and attraction, effectively disbanding clusters, and facilitating uniform dispersion.

Sedimentation, a common quandary in colloidal systems and suspensions, arises from the continuous struggle between gravitational forces and stabilizing mechanisms. Gravity often causes particles to gravitate to the container’s bottom, while the buoyancy of the surrounding medium exacerbates this process. Brownian motion, driven by thermal energy, provides a degree of resistance but may prove insufficient in certain scenarios. To combat sedimentation, stabilizers are introduced to impart buoyancy and disrupt the settling of particles. Adjustments in particle size or medium viscosity can further thwart sedimentation, preserving a stable dispersion.

Irreversible aggregation poses another challenge with far-reaching consequences for particle dispersion. It manifests when particles forge formidable bonds, like covalent or irreversible electrostatic interactions, which resist easy disruption and lead to enduring changes in particle characteristics and distribution. Mitigating this challenge necessitates a comprehensive understanding of the forces and conditions influencing and shaping irreversible aggregation. Ensuring stability throughout the process requires meticulous control over dispersants and dispersion conditions.

Balancing Benefits and Challenges: Engineered Surface Modifications in Dispersion

Engineered surface modifications, often employed to enhance particle dispersion, present a dual-edged sword. Chemical treatments or coatings on particle surfaces can reshape their interactions with the surrounding medium. Thus, achieving a balance between improved dispersion and potential side effects is crucial. These side effects may include unintended chemical reactions or alterations in reactivity. Therefore, achieving this equilibrium demands careful consideration of the specific material and application.

Additionally, material variability poses an inherent challenge in dispersion. Particles come in diverse shapes, sizes, surface properties, and charge characteristics. These factors profoundly influence dispersion behavior and the forces at play. Acknowledging and understanding these material-specific attributes is essential for developing tailored dispersion processes.

Dispersion Tools for dispersion in chemistry

The selection of appropriate laboratory and industrial equipment holds a critical role in the design and control of dispersion processes. The equipment choices significantly shape the interactions between particles and the surrounding medium, extending their impact far beyond mere facilitation. Combined they achieve precision and maintain consistency across a diverse range of industries.

High-speed mixers, ultrasonic probes, homogenizers, and a multitude of specialized devices become the guiding hands ensuring particles are evenly dispersed. High-speed mixers, for instance, employ mechanical forces to disintegrate aggregates and distribute particles uniformly. However, the

balance between speed and duration is important in preventing potential side effects. Ultrasonic probes harness high-frequency waves to achieve dispersion by generating microscopic bubbles in the liquid through cavitation. Homogenizers are reliable in creating stable dispersions, but settings must be precisely calibrated to avoid over-processing. Specialized devices cater to unique dispersion needs, but understanding their nuances and material compatibility is paramount. Equipment in dispersion is a double-edged sword; when chosen, calibrated, and operated wisely, it elevates the overall dispersion quality. However, inadequate selection or misuse can lead to unintended consequences. Achieving desired dispersion outcomes requires an artful blend of testing, equipment choice, settings, and material characteristics.

Dispersion unfolds

Dispersion is a multifaceted process characterized by intricate chemical interactions, particle-specific attributes, and a delicate balance of forces. This complex journey unfolds as bulk particles transform into an end product. Industries face various challenges, including agglomeration, sedimentation, irreversible aggregation, surface modifications, and material variability.

At each hurdle, from agglomeration to irreversible aggregation, researchers and engineers uncover opportunities for innovation. These discoveries drive industries forward, enabling progress and improved solutions.

In laboratories and production facilities focused on designing cosmetics, pharmaceuticals, and food products, mastering dispersion becomes an art. This mastery not only ensures product uniformity but also enhances effectiveness, appearance, and taste. The quest for perfection in dispersion and particle interactions is a continuous journey. With each discovery, we move closer to unlocking its full potential.