Stop Mixing Them Up

Teams often blur these terms. Dew point vs water activity is not a nuance. Dew point describes air moisture. Water activity, a_w, describes the powder’s moisture equilibrium. You need both to avoid caking, collapse, and dosing drift.

What Each Metric Actually Means

Dew point is the temperature where air saturates. It flags condensation on cold metal. It guides HVAC drying capacity. However, it does not predict product behavior.

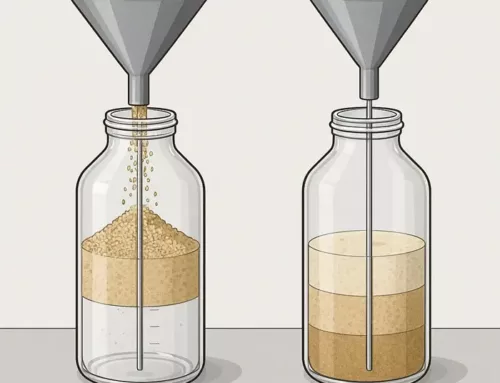

Water activity reflects the chemical potential of water in the powder. Materials seek an equilibrium a_w. Amorphous and porous matrices respond strongly to a_w. Structure follows sorption. Strength follows structure. Stability tracks a_w, not RH alone.

Link Room Control to Product Needs

Start simple. Measure a_w at room conditions. Build a three-point isotherm when possible. Take each point at the actual process temperature. Next, convert target a_w to RH at that temperature. Then convert that RH to a room dew point. Now HVAC supports the product, not rules of thumb.

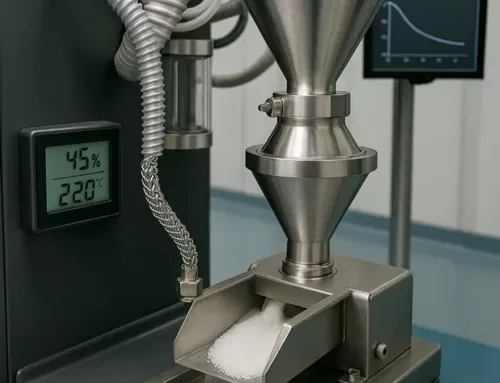

Run Lines with Practical Controls

Hold room dew point so RH stays below the critical a_w. Use local extraction near feeders. Keep refill air dry and filtered. Insulate cold surfaces to avoid wet spots. Then verify a_w on retains after key steps. Close the loop.

Avoid These Two Common Traps

Very low dew point can over-dry amorphous matrices. Tack can change and static often rises. You solve caking, then create dosing noise. Also track cooling between rooms. RH climbs when air cools across zones. Set dew point for the coldest credible surface.

Validate Fast and Keep Evidence

Use a handheld a_w meter at release. Place small RH and temperature loggers at three points. Record dew point from the BMS. Link deviations to flow tests. If ring shear flow drops on humid days, setpoints miss the mark.

Standard Targets You Can Publish

Set a product a_w window. Set a room dew point that guarantees that window at operating temperature. Define monitoring points and action limits. Train operators to react when either metric drifts. This dual-metric method prevents surprises.

FAQ Dew-point-vs-water-activity

What is the difference between dew point and water activity?

Dew point measures air moisture. Water activity measures a powder’s moisture equilibrium.

Why control both in powder processing?

Air control alone cannot assure stability. a_w drives collapse and caking risk.

How do I set targets?

Define a product a_w window. Translate it to RH at process temperature. Then set dew point to hold that RH.