Pneumatic conveying systems (PCS) are essential in industries that handle bulk solids, moving materials from fine powders to mm-sized granules. By suspending particles in an air stream, PCS can transport materials horizontally, vertically, or at an incline over distances ranging from a few meters to hundreds. With the system fully enclosed, there is typically no spillage or contamination—unless pipeline erosion occurs or an external force causes damage. This containment makes PCS a preferred choice in industries needing clean, efficient material transport.

How Pneumatic Conveying Systems Work

In PCS, either positive or negative compressed air moves material from a feeding hopper to a receiver. The receiver separates the material from the carrier air, completing the transfer. The range of materials suitable for PCS depends on particle size, hardness, and cohesiveness. Generally, materials with high cohesion or stickiness may block the pipeline, making them less suitable for pneumatic transport. PCS remains an efficient choice for conveying dry powders, granules, and pellets across various industries, including food, pharmaceuticals, cement, and petrochemicals.

Key Factor: Particle Velocity

Particle velocity significantly affects attrition and wear in Pneumatic Conveying Systems. In past research, Delft Solids Solutions demonstrated how adjusting velocity influences particle abrasion. Lowering or increasing velocity can have mixed effects, potentially reducing or increasing material degradation. Initial testing often sets air velocity between 10 to 50 m/s, close to slip velocity (particle velocity), for optimal results.

The pipeline’s design also influences erosion. Bends in the pipeline create impact zones where particles collide with walls, leading to wear. Minimizing bends helps reduce pressure drops and impact-related erosion, improving system durability and particle quality.

Erosion and its Effects

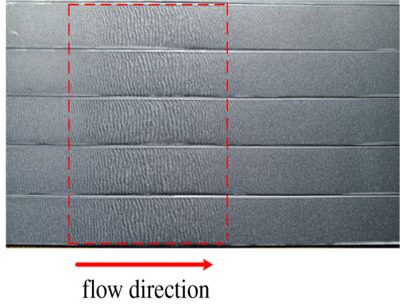

Erosion in PCS pipelines is most prominent at bends due to particle impact, angle of the bend, and material volume. Frequent collisions, especially with abrasive particles, cut into pipeline walls, causing erosion. This damage becomes a serious issue when conveying food substances like milk powder or sugar, where contamination from eroded pipe particulates can compromise quality and safety. Pipeline geometry—internal diameter, material quality, coupling alignment, and bend angles—plays a critical role in controlling erosion and maintaining particle quality.

Particle abrasiveness also affects erosion. For example, sugar is more abrasive than milk powder. Both surface erosion and particle attrition result from contact events during transport, with the hardness and toughness of particles and pipeline material determining the extent of wear.

Case Study: Erosion Analysis by Delft Solids Solutions

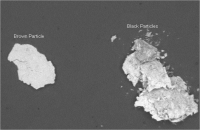

Delft Solids Solutions conducted a case study to analyze pipeline erosion. Using SEM-EDX equipment, researchers studied a pipeline conveying materials at 8 m/s containing elements like calcium and chlorine. Results showed erosion at nearly all bends, with dark erodent particles containing zinc and iron found throughout the transported material. These contaminants compromise product quality and safety, highlighting the need for regular sample testing to adhere to safety standards.

Delft Solids Solutions works with clients to find solutions, such as switching conveying methods, adjusting particle velocity, or modifying pipeline bends to minimize erosion.

Advancing Particle Science and Technology

Delft Solids Solutions examines erosion case

In the researched case study, the aforementioned erosion phenomenon in a pipeline was evident and shown with SEM-EDX equipment. In that study, a material containing Ca, CI, C, and O was being conveyed at 8 m/s.

The tests showed that nearly all bends in the pneumatic test rig had been affected and erosion of the pipe walls was evident.

Mitigating Contaminants in Pneumatic Conveying: Advancing Particle Science and Ensuring Product Quality

The dark particles visible in the image are eroded wall particles containing heavy metals like zinc (Zn) and iron (Fe). These contaminants appeared throughout the transported material, posing risks to product quality and safety. Regular sample testing in industrial plants helps maintain standards by identifying pollutants and finding solutions to reduce contamination. Possible adjustments include switching conveying methods, modifying particle velocity, or altering pipeline bend angles to minimize particle impact and abrasion, contributing to pipeline wall erosion.

Research, development, and testing are essential to advancing particle science and technology. Delft Solids Solutions dedicates its expertise and resources to testing, problem-solving, and designing efficient processing methods for the particle processing industries. With extensive research and field experience, our team at Delft Solids Solutions focuses on enhancing sustainability and driving technological progress in our field.