Moisture risk in powder formulations

Moisture risk in powder formulations is often treated as a checklist item. Teams log RH limits, then move on. That approach misses critical failure routes. Water rarely acts as a passive guest. It participates, transports, and transforms.

Limits of conventional hygroscopicity tests

Gravimetric tests remain useful first steps. They show equilibrium uptake and deliquescent points. However, mass change alone hides structural change. Surfaces, phases, and interfaces evolve under water activity.

Mechanistic pathways of water interaction

Water lowers surface energy at polar sites. Contacts weaken and rearrange. Transient films then enable solute mobility. Dissolved species migrate along pores and fissures. New internal interfaces form as a result.

Crystalline excipients respond in distinct ways. Some shift between polymorphs. Others partially amorphize and trap stress. Both outcomes change compressibility and dissolution. The blend can pass mass tests yet drift in performance.

Local chemistry and hidden risks

Local chemistry also accelerates. Water concentrates reactants in pores and defects. Hydrolysis and oxidation rates climb. Consequently, small moisture pockets can shorten shelf life significantly.

Why RH endpoints are not enough

Conventional RH endpoints miss these dynamics. They report numbers, not mechanisms. Therefore, you need tools that reveal interaction pathways. Methods must connect sorption to structure and behavior.

Advanced tools for moisture analysis

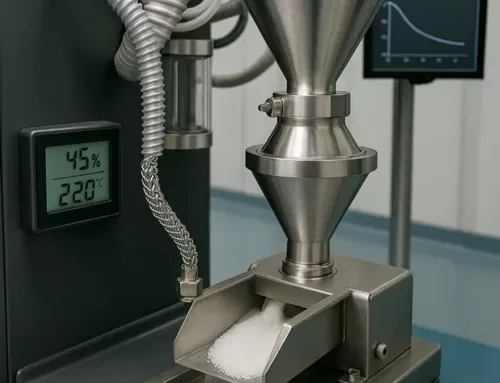

Dynamic vapor sorption (DVS) maps sorption and desorption. Hysteresis exposes structural lag and pore effects. Moreover, stepwise profiles reveal transitions across RH cycles. You see change, not just endpoints.

Inverse gas chromatography (IGC) quantifies surface energetics. Dispersive and specific components shift with RH. Consequently, you can link moisture to cohesion and flow. Flow issues often trace back to rising surface energy heterogeneity.

Thermal analysis adds complementary insight. DSC and TGA under controlled humidity show phase events. Glass transitions move with water content. Additionally, recrystallization on drying becomes visible and timed.

Microscopy closes the loop. SEM with EDS highlights redistributions of salts and excipients. FTIR microscopy tracks functional group movement. Together, images anchor the mechanism narrative.

Practical implications for formulation

Now consider practical risks. Recrystallization creates solid bridges after drying. Binders then lock neighbors together. Flow collapses during handling. Dosing drifts under vibration or time.

Actives near reactive sites degrade faster. Local water raises mobility and contact. Consequently, impurities or trace metals gain influence. Stability claims fail earlier than expected.

Packaging and process safeguards

Packaging choices often underperform. Barrier ratings reflect averages, not microclimates. Tiny leaks create RH gradients inside containers. Moreover, powders with internal porosity amplify gradients. Stability zones then fragment across the lot.

Formulators should test across cycles, not single points. Moisture moves with time and temperature. Therefore, simulate storage, transport, and process pauses. Capture hysteresis and lag explicitly.

Beyond excipient tables

Excipient tables offer incomplete guidance. Two materials with similar uptake can diverge radically. One may amorphize under stress. Another may recrystallize after drying. Design choices must reflect those paths.

Blend architecture also matters. Reduce pathways that focus moisture. Control pore networks and binder domains. Additionally, avoid pairing hygroscopic salts with catalytic surfaces. Small separations can delay failure.

Tiered testing strategies

Use a staged protocol. First, run DVS to define RH landmarks and cycling. Next, apply IGC at low and high RH to quantify surface energy shifts. Then, measure Tg shifts and recrystallization with humid DSC or TGA. Finish with SEM-EDS or FTIR microscopy to verify where species moved.

Interpret data as a system. Numbers must map to mechanisms. Thus, tie the sorption features to phase events. Link surface energy to flow and caking. Align images with kinetics and packaging behavior.

Building resilience into formulations

Risk controls follow naturally. Choose excipients with stable humidity responses. Use coatings that resist recrystallization. Additionally, specify liners with proven low permeation. Validate closures under thermal cycling.

Operations should protect the gains. Define RH windows for each step. Stage materials in controlled buffers. Consequently, line holds do not become hidden stress tests.

Conclusion: treating moisture as an active design variable

The core message is simple. Moisture is not only an environmental parameter. It is an active participant. It changes surfaces, phases, and reaction rates. Therefore, treat moisture as a design variable, not a limit note. Use advanced methods to see the pathways. Then build formulations that remain stable in the real world.