Featured articles

Powdertechnology.info insight of the week

Dilute phase vs dense phase conveying

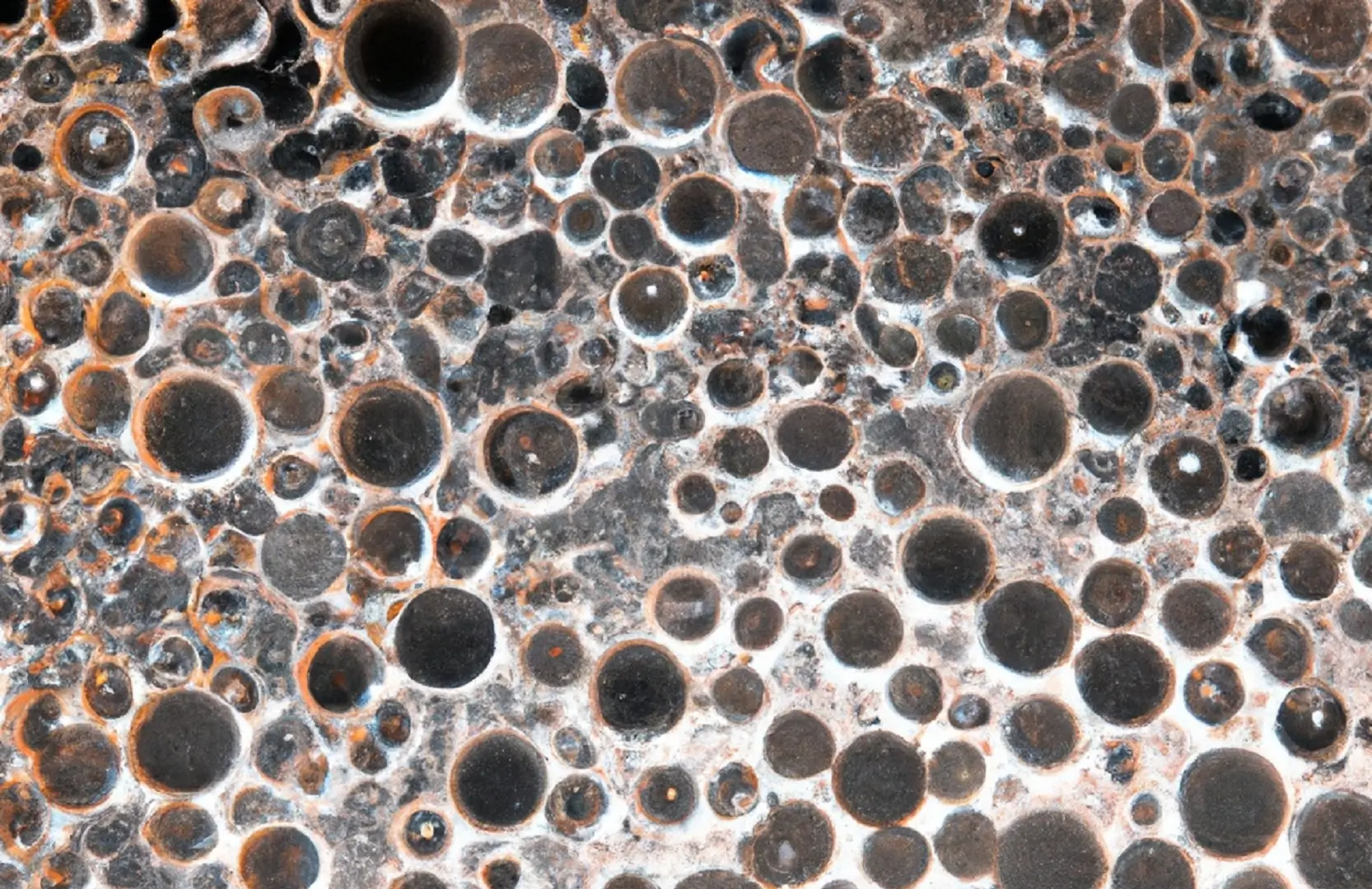

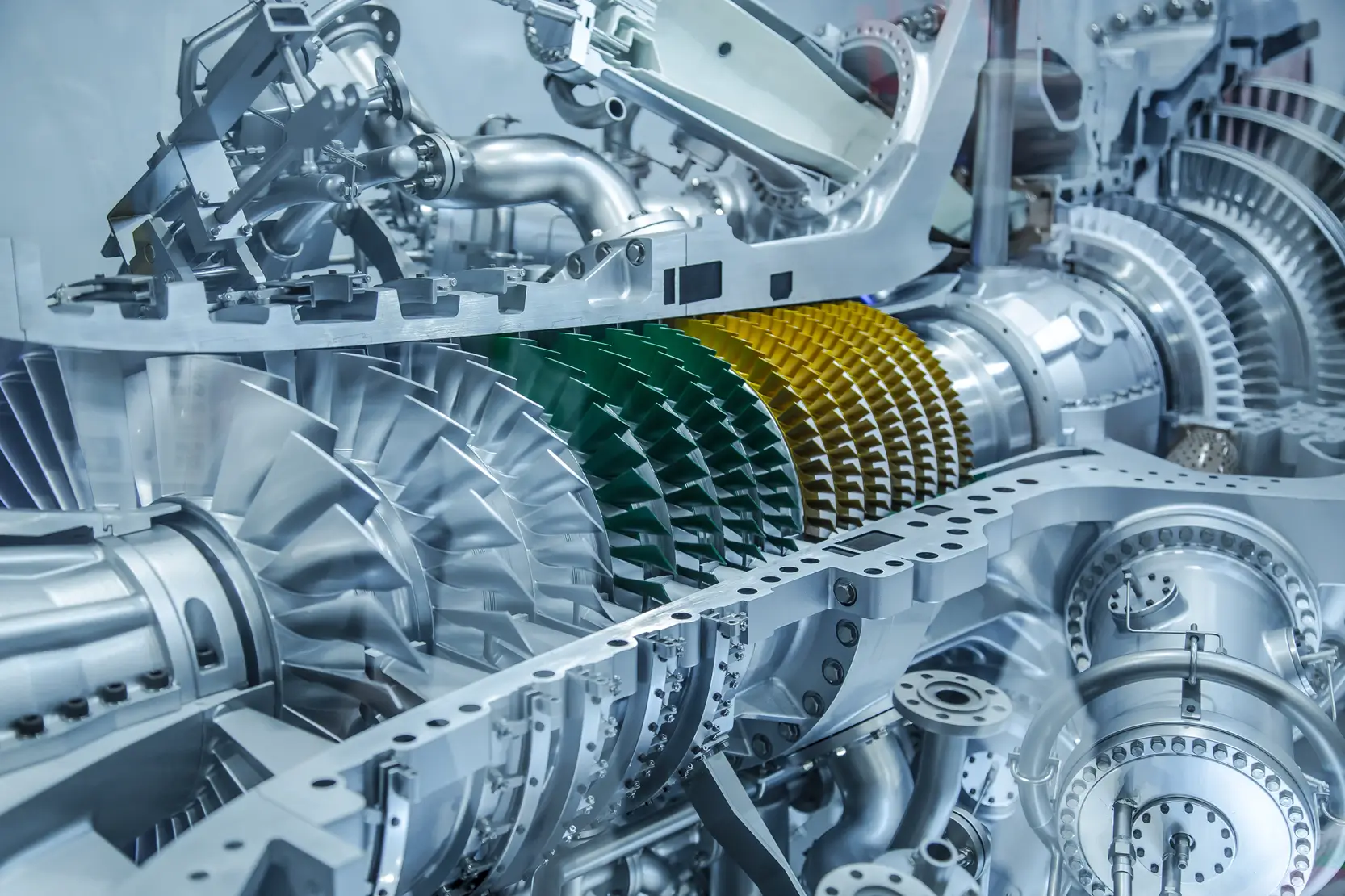

Pneumatic Conveying is the act of transporting solid particles through pipelines, using a gas (often compressed air) as the carrying medium. When designing a pneumatic conveying system, there are several considerations that should made. One such consideration is if the system should be used for dilute phase or dense phase conveying. Dilute phase conveying systems use high air velocities (15 – 40 m/s) and relatively low solid loading ratios to suspend the conveyed material in the air stream. On the other hand, you have dense phase conveying which utilizes low air velocities (< 15 m/s) and relatively high solid loading ratios to effectively push the material through the pipeline. Dilute phase conveying is the most utilized of the two conveying systems, as the material gets conveyed at a higher speed than when it gets conveyed using dense phase conveying. However, going fast is not always the best option. the pipeline. The large amount of force exerted on the particles will often lead to fragmentation and chipping of the particles. This is especially the case with more friable materials, such as lignin. When comparing the wear of lignin between comparable dilute phase and dense phase conveying systems, it was observed that approx 31% of the lignin introduced into the dilute phase conveying system had a reduced particle size. In the case of the dense phase conveying system this percentage was just 16%. For some industries this might not be a relevant problem, but it is important to keep in mind that the fastest option is not always the best option.

Figure 1: Dense phase conveying of lignin

Figure 2: Dilute phase conveying lignin

Figure 3 Dilute phase conveying lignin

Conveying systems often have bends and when the material is conveyed at high speeds through those bends, the material will often impact the wall of

Previous weekly insights

what’s trending

Monthly Top Tips

Our videos

Top Pick Articles

editor’s picks

Prime Archive content, selected by our editors.

Partner content

popular news & articles

News and articles in your inbox

Sign up and receive PowderTechnology.info news, articles, and content from our partners in a quick and easy monthly newsletter.

Popular this month

Events

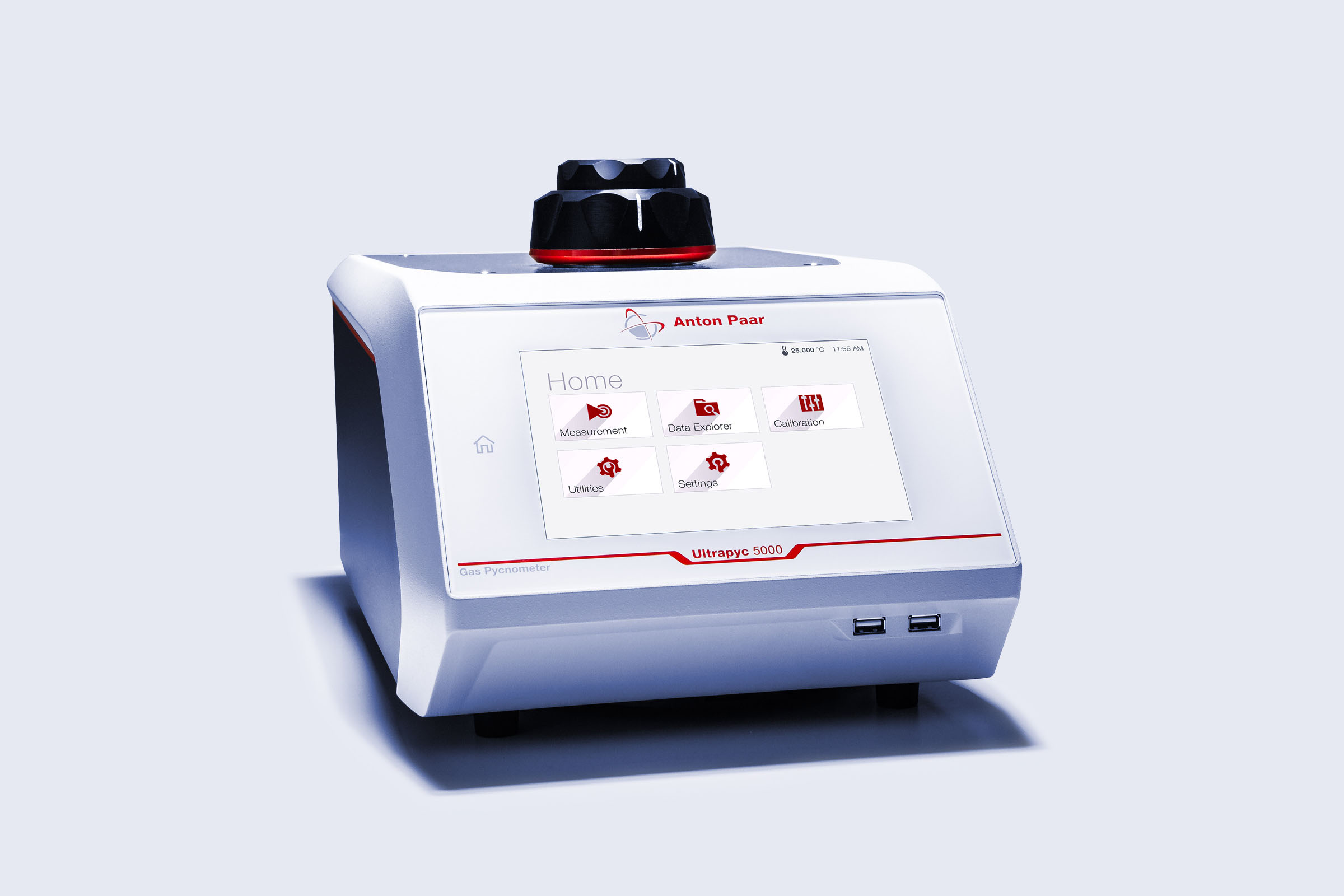

Delft Solids Solutions presents a comprehensive 2-day Particle Characterization course, intricately linked with a 1-day Porosity and Surface Area Characterization program. Designed for industries dealing with diverse materials, the course explores fundamental principles, definitions, and techniques for particle size and shape characterization. Key topics include sampling, sieving, sedimentation, microscopy, and quality control, with practical demonstrations reinforcing theoretical knowledge in the well-equipped laboratory. Scheduled for November 26-27, 2024, in Wateringen, The Netherlands, the course offers participants a profound understanding of particle characterization techniques, enabling them to interpret results and ensure measurement reliability. Upon completion, a certificate of participation is awarded. For inquiries or registration, contact Delft Solids Solutions at +31 174 271 460 or info@solids-solutions.com.