Featured articles

Powdertechnology.info insight of the week

Previous weekly insights

what’s trending

Monthly Top Tips

Our videos

Top Pick Articles

editor’s picks

Prime Archive content, selected by our editors.

Partner content

popular news & articles

News and articles in your inbox

Sign up and receive PowderTechnology.info news, articles, and content from our partners in a quick and easy monthly newsletter.

Popular this month

Events

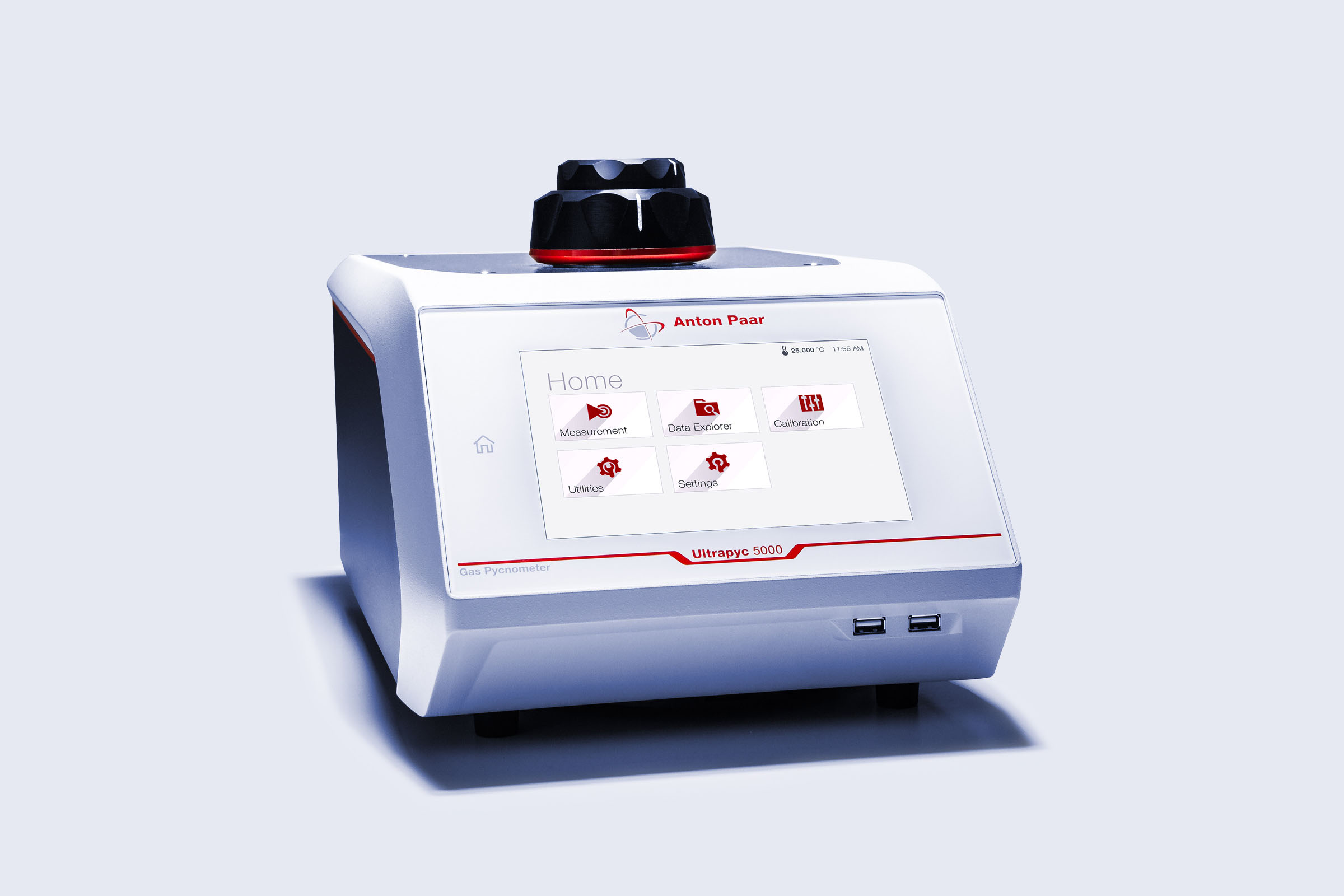

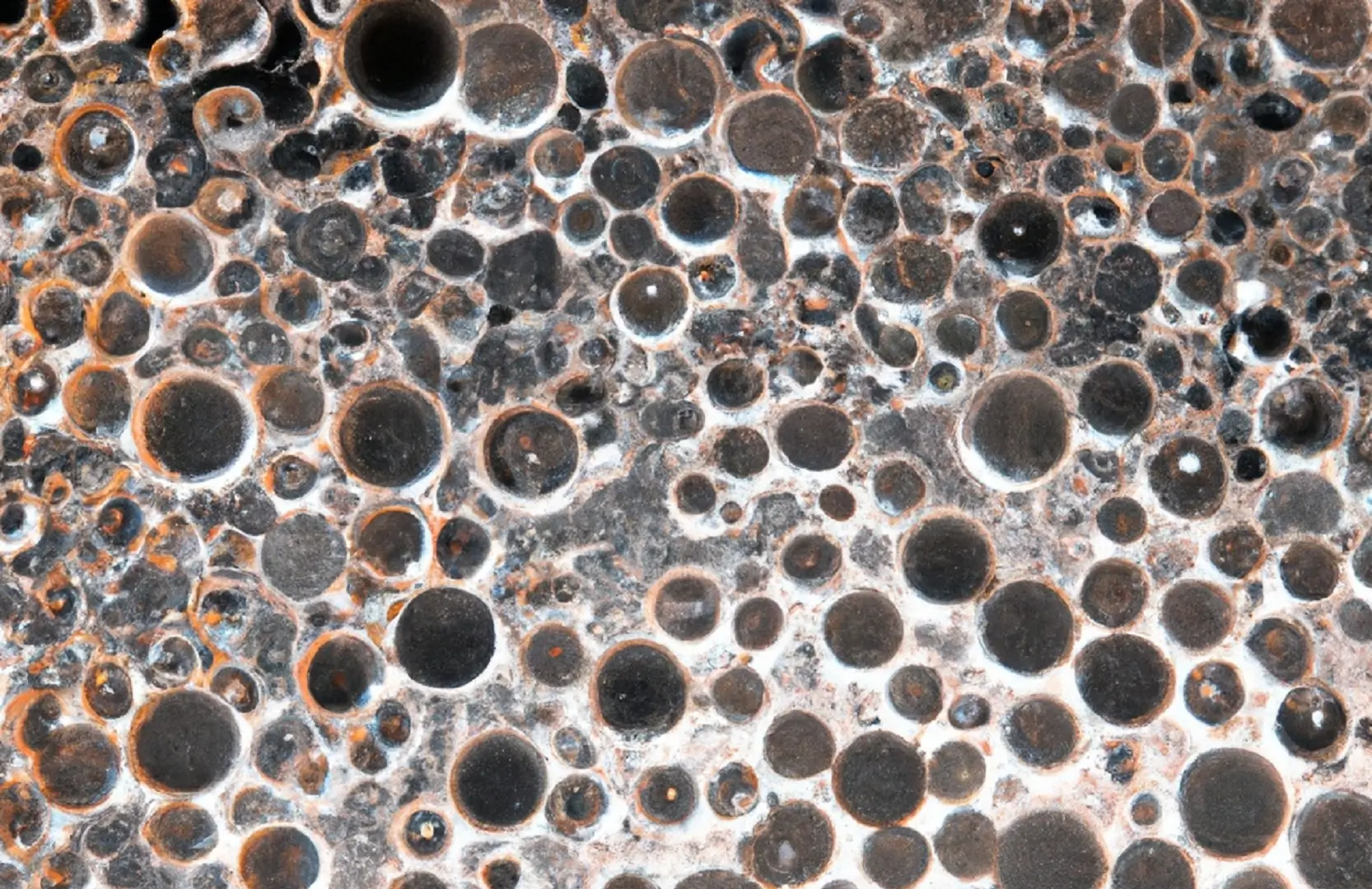

Delft Solids Solutions presents a comprehensive 2-day Particle Characterization course, intricately linked with a 1-day Porosity and Surface Area Characterization program. Designed for industries dealing with diverse materials, the course explores fundamental principles, definitions, and techniques for particle size and shape characterization. Key topics include sampling, sieving, sedimentation, microscopy, and quality control, with practical demonstrations reinforcing theoretical knowledge in the well-equipped laboratory. Scheduled for November 26-27, 2024, in Wateringen, The Netherlands, the course offers participants a profound understanding of particle characterization techniques, enabling them to interpret results and ensure measurement reliability. Upon completion, a certificate of participation is awarded. For inquiries or registration, contact Delft Solids Solutions at +31 174 271 460 or info@solids-solutions.com.