In a groundbreaking development, researchers at the University of Illinois Urbana-Champaign, in collaboration with the National Energy Technology Laboratory, Oak Ridge National Laboratory, and the Taiwan Semiconductor Manufacturing Company (TSMC), have successfully transformed coal into high-purity materials poised to reshape the landscape of next-generation electronic devices. This significant stride not only opens up new avenues for the economic use of coal but also heralds a crucial shift toward sustainable and advanced technology.

Redefining Coal: From Fossil Fuel Transforming Coal for Nanoelectronics

Traditionally perceived as a bulky and dirty energy source contributing to climate change, coal is now being reimagined as a key player in the evolution of nanoelectronics. The research team, led by Qing Cao, a materials science & engineering professor at the University of Illinois, has developed processing techniques capable of converting coal into high-purity materials just a few atoms thick. These materials boast unique atomic structures ideal for crafting exceptionally small yet high-performing electronics.

Transforming Coal for Nanoelectronics: From Coal Char to Carbon Dots – The Innovative Conversion Process

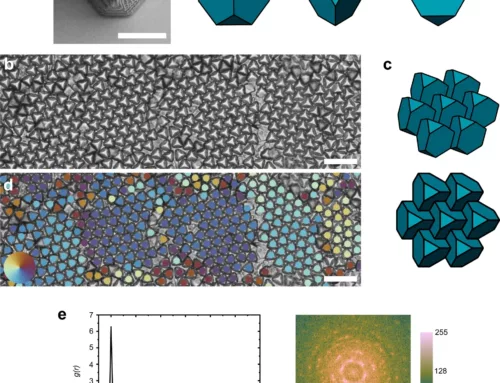

The process initiated by the National Energy Technology Laboratory involves converting coal char into nanoscale carbon disks known as “carbon dots.” The University of Illinois research group demonstrated that these carbon dots can be interconnected to form atomically thin membranes suitable for applications in two-dimensional transistors and memristors. These technologies are anticipated to play a pivotal role in the construction of more advanced and efficient electronics, as highlighted in the recent publication in the journal Communications Engineering.

Pioneering Two-Dimensional Electronics

The ongoing quest for smaller, faster, and more efficient electronics has led researchers to explore devices made from materials just one or two atoms thick. The use of ultrathin semiconductors has been extensively studied, but it is equally crucial to have atomically thin insulators that block electric currents. The researchers have shown that atomically thin layers of carbon derived from coal char can function as excellent insulators, opening up new possibilities for constructing two-dimensional devices.

Coal-Derived Carbon Layers: A Game-Changer in Transistors

The University of Illinois group, under Cao’s leadership, demonstrated the groundbreaking application of coal-derived carbon layers as gate dielectrics in two-dimensional transistors. These transistors, built on semimetal graphene or semiconductor molybdenum disulfide, exhibited more than twice the operating speed with lower energy consumption compared to conventional materials. The unique properties of coal-derived carbon layers, being amorphous and lacking crystalline structures, contribute to reduced power consumption during device operations.

Fueling the AI Revolution: Memristors with Coal-Derived Carbon Layers

Beyond transistors, the researchers explored the use of coal-derived carbon layers in memristors, electronic components capable of both storing and operating on data, crucial for advancing AI technology. The adoption of ultrathin coal-derived carbon layers as insulators in memristors facilitated the fast formation of conductive filaments with low energy consumption, leading to high device operating speeds with low power.

Challenges and Collaborations: Scaling Up for Industrial Production

While these developments showcase the proof-of-principle for coal-derived carbon layers in two-dimensional devices, the next challenge lies in demonstrating their scalability for industrial production. Collaborations with industry partners, including Taiwan Semiconductor, are underway to develop a fabrication process that can be implemented on a large scale.

Conclusion: A Quantum Leap – Transforming Coal for Nanoelectronics

reference: DOI: 10.1038/s44172-023-00141-9