Photolithography and Etching

In the first part of our series on lab-on-a-chip technology, we looked into various scientific disciplines, including microfluidics, materials science, chemistry, and engineering, that have led to the development of the lab-on-a-chip analytical approach. The article gave a perspective on how advancements in microfabrication techniques, particularly photolithography and thin-film deposition, have enabled precise manipulation of fluids and materials at the microscale. To continue we will look deeper at what photolithography entails when it comes to lab on a chip fabrication.

Photolithography

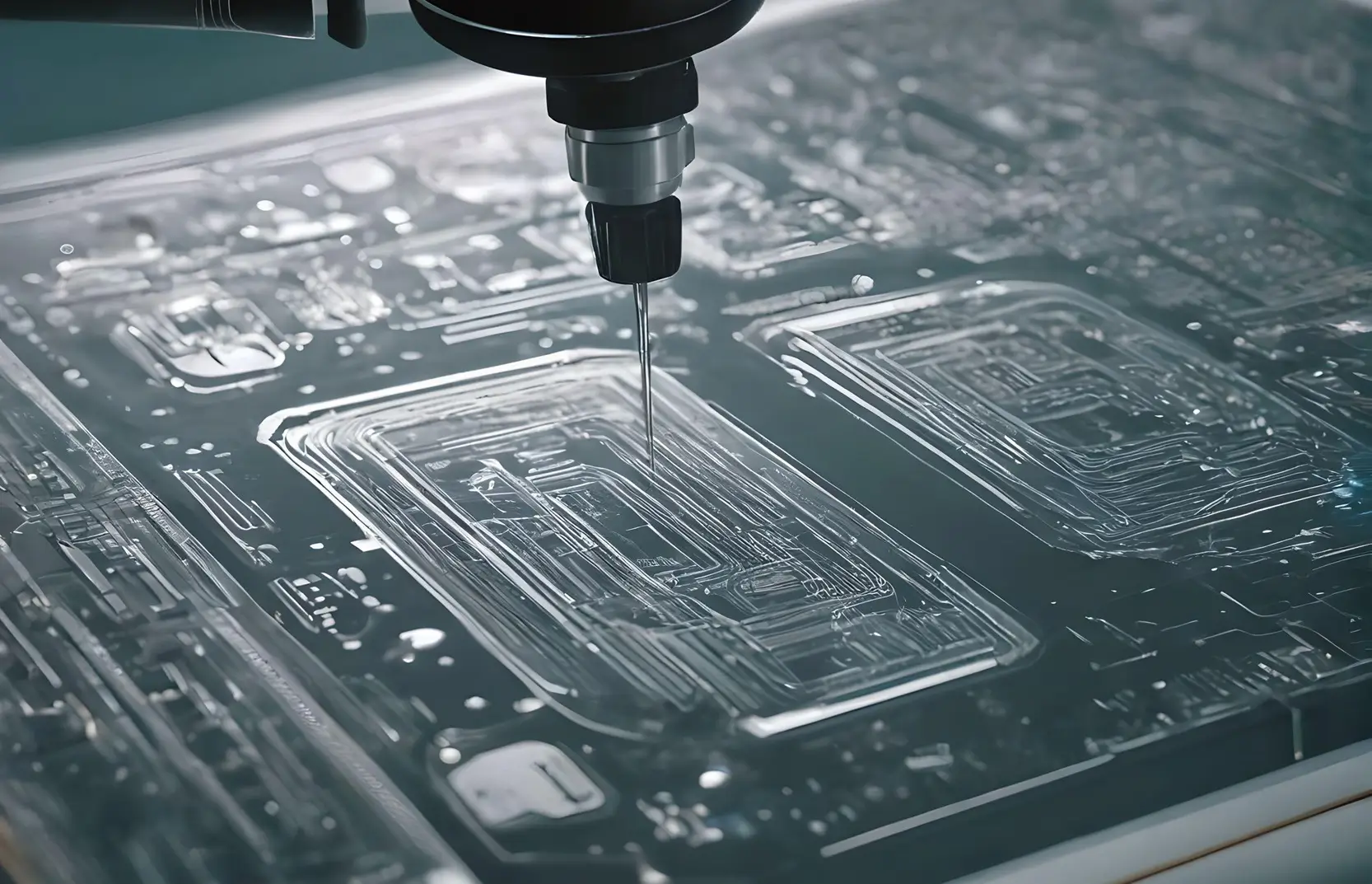

Photolithography is a key technique for fabricating lab-on-a-chip devices, used to define complex microscale features on substrates. The process involves patterning photoresist layers with masks and UV light exposure. Below, we detail the steps—coating, exposure, development, and post-exposure bake—and emphasize the precision needed to define microscale features.

Before photolithography begins, the substrate (silicon, glass, or polymer) is thoroughly cleaned. This step removes contaminants and ensures proper adhesion of the layers, crucial for uniform coating and accurate photoresist patterning.

Spin-Coating and Patterning

The substrate is spin-coated with a photoresist layer. This light-sensitive material changes chemically when exposed to UV light. The photoresist thickness is controlled to achieve the desired feature dimensions. Spin-coating ensures uniform coverage of the substrate for precise patterning.

A photomask with the desired pattern aligns with the coated substrate. The photomask has opaque regions that block UV light and transparent ones that allow it through. This creates the desired pattern on the photoresist layer. The substrate is exposed to UV light, activating the photoresist in exposed areas and leaving unexposed areas unaffected.

After exposure, we immerse the substrate in a developer solution that removes the unexposed regions of the photoresist, leaving behind the patterned layer. We carefully control the development process to ensure complete removal of the unexposed photoresist while preserving the patterned features with high fidelity. This proper development is critical for achieving accurate and reproducible microscale features.

Next, we conduct a post-exposure bake process to further stabilize the patterned photoresist layer and enhance its adhesion to the substrate. This step involves heating the substrate at a specific temperature for a predetermined duration, allowing the photoresist to crosslink and harden effectively.

We need the post-exposure bake step to improve the durability and reliability of the patterned features, especially during subsequent processing steps like etching or deposition. The photolithography process demands a high level of precision and control to achieve microscale features with sub-micron resolution.

We must carefully optimize factors such as photoresist thickness, exposure dose, and development time to ensure accurate pattern transfer from the photomask to the substrate. Additionally, we must align the photomask precisely with the substrate to avoid misalignment errors that could compromise the integrity of the final device.

Photolithography

Photolithography plays a crucial role in fabricating lab-on-a-chip devices. It enables researchers to define microscale features precisely for fluidic channels, chambers, and electrodes. By carefully controlling each aspect of the process, researchers achieve high-quality patterns with exceptional accuracy and reproducibility. This precision lays the foundation for advanced microfluidic systems, supporting various scientific and medical applications.

Etching

Etching techniques play a crucial role in transferring patterns from the photoresist layer to the substrate. They define channel geometries and depths in lab-on-a-chip devices. Common etching methods include wet and dry etching. Each method offers unique advantages and control over the etching process.

Wet etching involves selectively removing material from the substrate using liquid chemical etchants. The choice of etchant and conditions depends on the substrate material and desired etch rate. Common wet etchants include acids, bases, or solvents. These substances react with the substrate to dissolve or dislodge it selectively.

The choice of etchant also determines selectivity and etch rate. Different etchants exhibit varying selectivity toward materials, allowing for better control. Etching temperature affects both etch rate and selectivity. Higher temperatures usually lead to faster etch rates. However, they also increase the risk of non-uniform etching or damage to the photoresist layer. The duration of the etching process determines the depth of channels or features. Careful control of etch time helps achieve desired geometries and depths without over-etching.

Dry Etching Processes: Precision and Control

Under-etching occurs during the dry etching process, also known as plasma etching, when reactive ions or gases remove material from the substrate in a plasma environment instead of using liquid etchants. This method offers higher precision, selectivity, and control compared to wet etching. Common dry etching techniques include reactive ion etching (RIE), inductively coupled plasma (ICP) etching, and deep reactive ion etching (DRIE).

To achieve desired outcomes, we carefully control dry etching parameters by selecting appropriate process gases, as their composition impacts the etch rate, selectivity, and sidewall profile. Reactive gases, such as fluorine-based or chlorine-based compounds, react with the substrate to form volatile byproducts, which we subsequently remove. The plasma source power influences the density and energy of the ions impacting the substrate. Additionally, we control the pressure within the etching chamber to achieve uniform etching and minimize sidewall roughness.

Precision Etching Techniques

Both wet etching and dry etching techniques offer precise control over channel geometries and depths in lab-on-a-chip devices. By carefully selecting etchants or process gases, controlling etching parameters such as temperature, time, plasma power, and pressure, researchers can achieve the desired channel dimensions, aspect ratios, and surface roughness. For example, wet etching may be preferred for shallow channels with smooth sidewalls, while dry etching techniques offer superior control over feature dimensions and aspect ratios, making them suitable for deeper and high-aspect-ratio structures. Additionally, advanced techniques such as deep reactive ion etching (DRIE) enable the fabrication of deep, vertical features with high aspect ratios, essential for applications such as microfluidic channels and through-silicon vias (TSVs).

Finally by choosing the desired etchants or process gases and optimizing the etching parameters, researchers can achieve the desired channel geometries and depths required for various microfluidic applications, advancing the development of next-generation lab-on-a-chip devices for scientific and medical research.

Conclusion

In this segment, we explored the process of photolithography. Specifically, this key step fabricates microscale features for fluidic channels, chambers, and electrodes. Moreover, photolithography allows researchers to precisely define microstructures essential for lab-on-a-chip devices, which are revolutionizing scientific research and healthcare.

In the next part of our series, we will examine thin-film deposition. This technique, therefore, enhances lab-on-a-chip devices by coating substrates with specialized materials. Additionally, it creates electrodes, sensors, and functional coatings to improve device performance.