Nano-dust and the CEN guidelines

Nanomaterials are produced and used by many European industries, including in the manufacture of chemicals. The production and use of these materials are subject to both EU-wide regulations and national legislation. Employers should ensure that workers have both the knowledge and the equipment to use these materials safely.

Since nanotechnology is used to produce a wide range of products and solutions, many workers can be exposed to nanomaterials at work. Nanomaterials are often produced in closed systems, but exposure can also take place during maintenance work or during the handling of finished products.

Legislative guidlines are therefore of the utmost importance. The European Union is pushing the development of new technical standards for nano-materials. This comprises of standards that can also be used for characterizing the exposure to nanomaterials in the workplace. The European Commission has issued a specific directive to develop new standards related to nanomaterials in the workplace. Several technical committees are working on this mandate, including CEN.

Nano-dust and the CEN guidelines

The Comité Européen de Normalisation also known as the European Committee for Standardization introduced the NEN-EN 17199-4:2019 the EN 17199-4 for short, in February of 2019. Essentially the document offers a guideline for the Measurement of dustiness of bulk materials that contain or release respirable NOAA or other respirable particles in relation to workplace exposure, the 4 in the name refers to part 4 specifically focusing on the small rotating drum method.

What are NOAA’s

.

Nano-dust and the CEN guidelines and NOAA

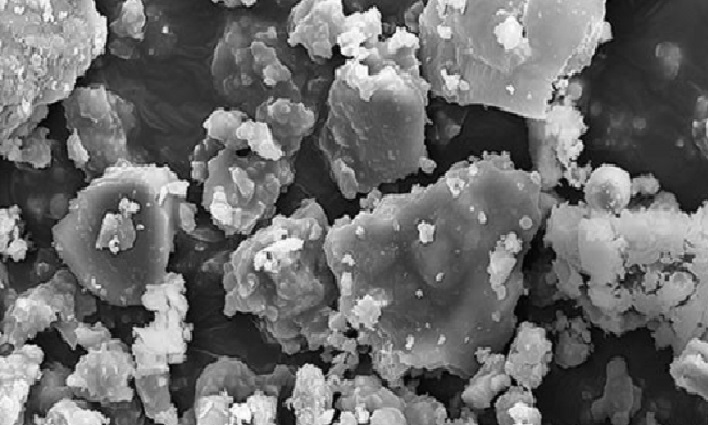

NOAA stands for (engineered) nano-objects and their aggregates and agglomerates. But what are these NOAA? NOAA have found a wide array of applications in many different production processes and industries. NOAA can generally been viewed as structures on a scale comparable with viruses, molecules or in some cases even atoms and can be found in industrial processes such as silver nanoparticle synthesis, production of thin nanocarbon layers, 3D-printing based on a nanohydroxyapatite-polymer composite and so on. Health risks and NOAAApart from its many advantages, the use of engineered nanomaterials can also threaten human wellbeing, primarily because of their potential toxicity.While human exposure to NOAA may in theory happen during any stage of the material lifecycle, it is most likely to occur in the workplace where these materials are produced or handled in either large quantities or over long periods of time. Because of its small size, diameter in 100 nm range, the material is easily absorbed either through the skin or through inhalation. The respiratory system is one of the primary methods of exposure in the work place. The inhaled nanomaterials, because of its small size, can reach the bloodstream, passing through membranes and accumulate in the organs which may lead to the compound crossing of the blood-brain barrier. These nanometer NOAA compounds can be internalized by cells and affect basic cellular activities such as metabolism, proliferation and differentiation.

.

Spirometry, body box and diffusion

There are generally three types of airway examination:

– spirometry which determines how much air you can move

– body box measure the resistance of your airways and lung contents

– diffusion measure the extent to which your blood absorbs oxygen from the lung

Challenges when measuring Nano-dust

.

The problem that arises when measuring nanoparticles is that many instruments are non-specific. The measured results don’t distinguish between the engineered nanoparticles from environmental nano size particles. For this a three-tiered approach was written based upon a systematic evaluation of previously proposed and used strategies and assessments. The EN 17199-4 has a different approach to this.

.

What does the EN 17199-4 specifically refer to?

.

The EN 17199-4 sets out to give clear guidelines in regards to dustiness measurement and characterization to provide manufacturers and producers with information on the potential for dust emissions when materials are handled, processed or stored. These guidelines provide the manufacturers and handlers of bulk materials with information that can help to reduce dustiness. It gives the required guidelines for handling and working with the NOAA materials. The small rotating drum method has been designed to simulate workplace scenarios and to represent general bulk material handling processes, such as materials being poured, mixed, scooped, dropped or tipped. The small rotating drum method presented EN 17199-4 differs from the rotating drum, continuous drop and the vortex shaker methods.The rotating drum and small rotating drum methods both perform, repeated pouring and agitation of the bulk solids material. The small rotating drum (SRD) method described in the EN 17199-4 measures the dustiness of bulk materials in terms of the respirable dustiness mass fraction, the number-based dustiness index, the number-based emission rates and the time period it takes to generate 50% of the emitted particle numbers.

.

Non-commercial apparatus a Special project

Although standardized, currently there are no commercially available products that fulfill these direct measurement needs. Together with Professor Dr. Keld Alstrup Jensen Msc. One of the principal writers of the EN 17199-4. we are working towards building a new Nano-dust measuring technology as based on the methodology mentioned in the EN-17199-4.

We expect to have this new set up ready in 2021. Interested in staying informed, let us know by sending us anemail.

The SRD method has been applied to test powders, granules or pellets containing or releasing respirable NOAA or other respirable particles in either unbound, bound uncoated and coated forms.

The dustiness of a range of materials including nanoparticle oxides (such as TiO2 and SiO2) and nanoflakes, organoclays, clays, carbon black, graphite, carbon nanotubes, organic pigments, and pharmaceutical active ingredients.

The method has thereby been proven to enable testing of a many different materials that can contain nanomaterials as the main component.