Particle technology is a rapidly growing industry, covering the science, research, testing, and processing of particles and powder-based materials. These particles range in size from nanometers to centimeters and play critical roles across industries like chemicals, food, pharmaceuticals, energy, agriculture, and biotech. With the emergence of nanotechnology, particle technology is advancing future technologies, as nanoparticles exhibit unique chemical, biological, and physical properties that open doors to new, robust materials.

Key applications of particle technology include milling, powder flow, size enlargement, pneumatic conveying, drying, and separation processes. Its scalability and complexity make particle technology unique. This field also fosters scientific collaboration, pushing particle physics beyond isolated sciences. Just as the internet connected computers globally, particle technology is evolving as a new phase in complex technological advancements.

The Benefits of Particle Technology

Particle technology enables industries to process, manipulate, and design solids in ways that enhance products and promote sustainability. By adjusting particle sizes, shapes, and other characteristics, companies can improve processes and products across multiple sectors.

For example, in biomedicine, particle technology helps analyze protein structures. In additive manufacturing, lasers sinter powdered materials, allowing rapid prototyping. In pharmaceuticals, it modifies dissolution rates for better formulations. Food processing benefits from particle manipulation, impacting texture and flavor. Particle technology also enhances paint formulations, battery charge speeds, cement cohesion, cream absorption, and fuel lubricants.

Cities use particle technology for water management, creating filtration systems that ensure safe drinking water. Particle technology is woven into product design and manufacturing across many sectors, adapting to changing demands for durability and ecological responsibility.

What Delft Solids Solutions Offers

With over 40 years of expertise, Delft Solids Solutions (DSS) provides state-of-the-art laboratory and testing facilities. Our advanced capabilities allow us to measure numerous physical particle characteristics across diverse industries. Using techniques such as porosity screening, particle size and shape testing, image analysis, and thermal analysis, we offer a wide range of problem-solving solutions that drive advancements in particle research and technology.

The Importance of Particle Testing

A single particle characteristic can impact a solid product’s performance. It’s crucial to investigate microscopic and macroscopic particle morphologies to understand, modify, and predict product behavior during processing. This testing enables production facilities to fine-tune their equipment, ensuring that particle applications meet their intended purpose effectively.

Our Approach at Delft Solids Solutions

As an independent contract research lab, DSS specializes in testing, consulting, and solving complex particle handling and processing issues. Our high-quality testing data, innovative solutions, and commitment to open communication help us build lasting business relationships with clients. We conduct investigations closely with clients, replicating conditions that mirror real-world applications. Our comprehensive array of instruments and custom-designed setups allows us to tackle complex challenges effectively.

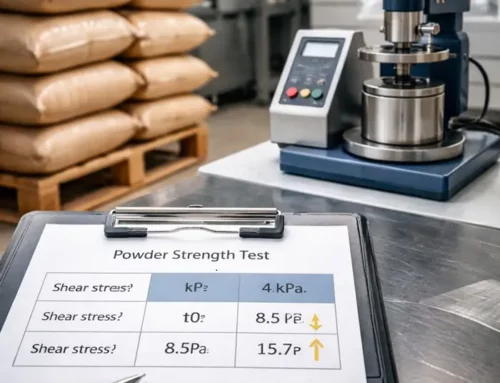

Reporting and Quality Assurance

DSS provides comprehensive research reports, presenting results clearly in both graphical and tabular forms for easy interpretation. Each report not only includes a detailed discussion of the findings but also provides essential background information and an in-depth explanation of the methodologies used. Additionally, we ensure that every report meets our rigorous standards of quality, precision, and sustainability. By delivering high-quality, reliable data, DSS supports industries in making informed decisions that drive advancements. Ultimately, our commitment to excellence helps industries thrive through the transformative power of particle technology.