Nature offers three compound types, conductive, semi-conductive, and insulative. Semiconductors are built up of different layered substances, the majority of which are composed of crystalline powder materials which can consist of silicon (Si), gallium (Ga), galena (Gn), selenium (Se), Indium (In), copper (Cu), cadmium (Cd), germanium (Ge) to name a few. These compounds are in-between being conductive and insulative and are used in electronic devices to open or close electrical circuits under certain conditions. All these compounds have different properties while in use, different heat tolerances, light refraction indexes, electron availability, etc. making semiconductors suitable for a wide array of different applications.

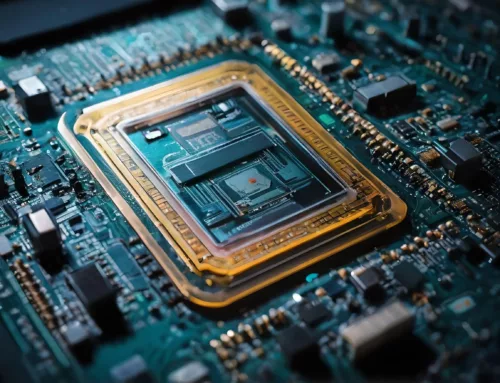

Semiconductors are used in everyday electrical appliances by both the consumer market, military defense, and aerospace. An example of a semiconductor would be a microchip, which uses integrated circuits that are composed of semiconductor material to perform predefined tasks. The efficiency of those tasks can be affected by external factors such as the materials used, the cleanliness of the production facility, their size, purity, circuit design, heat, magnetic fields, light refractive index, and the current that flows through it.

Germanium over the past seven decades

Germanium is one such semiconductor material among others that was used around 1947 to build the first working transistor. Since then other semiconductor materials like high-purity silicon which is more readily available have mostly replaced germanium. Added to that silicon is cheaper to produce, resists higher temperatures, has fewer free electrons, and has a lower conductivity than germanium. Silicon still by far exceeds germanium semiconductor production. But things change as technology methods advance which opens up new ways to utilize compounds previously less interesting to use, too expansive to fabricate, or had technology boundaries.

Around 1980 the use for Germanium was found to be a better material in designing gamma rays / infrared detectors, and fiber optics for NASA, and to this day it is still being used in high-speed, performance transistors, specialized semiconductors, as a resin for polyethylene plastics, phosphors production, glass colorants, other electronic compounds and in algaculture as an inhibitor. Silicon-based semiconductors still work very well for everyday electronics but as we are demanding and creating more complex systems, the need for more flexibility from the semiconductor material arises. For now, Silicon semiconductors have reached their limits of efficiency and speed. But this does not stop research and efforts to solve problems encountered when trying to design something new or improve the old and so continued research in particle sciences has given germanium a chance to shine again, as an attractive material for aerospace, military defense equipment, microchips technologies, and photovoltaics.

What is Germanium

Germanium is an inorganic byproduct of Zinc ore processing and is classified as a critical mineral in the United States due to its importance in industry sectors, such as defense and telecommunications. Presently global germanium production is at 140 metric tons per annum. Interestingly most of the processing is done in mainland China with an estimated yearly production of 95 metric tons. Currently, China is the world’s largest germanium producer. Past germanium producers in Africa using extraction from coal and lignite have stopped due to environmental concerns and mineral imposed regulations. New applications for germanium are developed because it has more free electrons and a higher conductivity rating than other materials, which could push the envelope and improve efficiencies in electron transfer speeds and multi-junction cells.

Multi-junction germanium cells

For a while now the next-generation germanium-based multi-junction solar cells have been the chosen material for high-demand integrated circuits. Multi-junction solar cells have multiple p-n junctions that produce current at different wavelengths depending on the material used, each material such as germanium, silicon, and indium all have different wavelengths. Germanium-based multi-junction photovoltaic cells can deliver increased power efficiency, save weight, and reduce production costs and the unit mass is smaller compared to traditional semiconductor materials like silicon. Therefore germanium is of interest to be used for both defense and aerospace industries. Another benefit for germanium is that it is resilient against extreme environments such as in space where there is no ozone layer to offer protection, the radiation levels are much higher and solar cells are being bombarded by protons and electrons that cause irreparable damage. This reduces the equipment’s lifespan and overall efficiency which is costly and not desirable for a satellite in orbit that cannot be repaired easily. Extreme temperatures from hot to cold require equipment that can withstand the harsh environment for decades.

The gains are in power efficiency and durability for the same power generation as conventional semiconductors. This will lead to smaller compacter satellites and as a result lower launch costs due to weight savings of the germanium-based photo voltaic cells and other components. As space-based applications for GPS, cellular, radio, TV, weather, astronomy, surveillance, global communications, environmental monitoring, and measurements more efficient satellites will be needed to carry more equipment to facilitate global technological advancements in the coming decades.

Chips are simplistic in that they always do the same thing repeatedly, with the only choice being 1 or 0 (on or off). With continued research, new perspectives, and fabrication processes the properties of germanium can now be used more efficiently and with an added layer of possibilities. Ongoing experimental research with germanium shows great potential that opens up new avenues in applications for artificial intelligence and neural networks. The possibilities are an increase in transistor choice functions and the ability to change chip circuits directly. This could really help develop AI and other technologies to another level. The next few years will probably show how germanium can be implemented and help solve certain challenges in semiconductor fabrication and utilization.

Commercial application

Despite the benefits of greater efficiency in germaniums photovoltaic solar cells construction, roughly 90% of the global earthbound solar cell industry uses silicone-on-glass based (SoG) cells because they are much cheaper however they also cause chromatic aberrations.

For several years now the industry has been looking into sustainable energy to reduce greenhouse gases. However, designing highly efficient solar cells at low costs remains a significant industrial challenge. For example, solar cells that use optics to focus solar energy on state-of-the-art multi-junction solar cells can play a large role in increasing solar power. Present the most efficient photovoltaic cells using indium phosphide (InP) substrates to convert solar radiation into electrical energy. However indium as a base substrate is even more expensive than germanium, So for now that is not a viable option and needs more research to lower the production cost. Germanium, on the other hand, has the potential for large-scale consumer-based implementation in the solar panel industry as advancements in powder technology and semiconductor designs are improving.