Bio-degradable Fertilizer types and Coating

A fertilizer is traditionally any material, organic or artificial in origin that is applied to the soil or the tissues of plants, to supply the crop with necessary nutrients and enhance productivity crop yields. There are many sources of fertilizer, most modern agricultural practices focus on three main categories of macronutrients: Nitrogen (N), Phosphorus (P), and Potassium (K) with depending on the type of crop fertilized, occasional supplementing of specific nutrients such as rock dust for micronutrients. Farmers and growers utilize these fertilizers in a variety of ways: through dry or pelletized or liquid application methods, using large agricultural machinery, or hand-tool equipment.With the industrialization and scientific breakthroughs made in the 1800s, the landscape of fertilization changed and lead to innovations in plant nutrition, and cultivated a new type of agricultural industry that thrived through the use of synthetically-created fertilizers.

Importance of Fertilizers in relation to increasing population growth

Bio-degradable Fertilizer Coating

This ultimately resulted in the transformation of the global food system, allowing for large-scale industrial agriculture with substantial crop yields. since the 1800s the world population has grown sevenfold. Which has led to the continuous need for crop innovations. Many strides have been made since then and now, but there is a need for product yield efficiency in terms of growth, to keep up with the increasing population with fewer resources. Loss of soil fertility, pests, and lack of nutrients resulted in a decrease in agricultural production. Between 1961 and 2021 the use of nitrogen fertilizers grew by 800%. This led to a 30% per capita increase in the productivity of conventional farming methods.

Types of Fertilizers

Bio-degradable Fertilizer Coating

There are generally two types of fertilizers, the inorganic and organic fertilizers and these consist of Nitrogen Fertilizers, Phosphorus Fertilizers, et cetera.

Nitrogen Fertilizers

Nitrogen is the main component of chlorophyll which is important in creating a balanced photosynthesis process. Nitrogen is also part of amino acids in plants. Nitrogen fertilizers have an increased production yield and crop quality.

Phosphorus Fertilizer

The efficiency of a fertilizer hinges on an effective phosphorus content. Phosphorus is found in the protoplasm of the cells and is crucial to cell growth and reproduction. The phosphorus fertilizer is invaluable for the development of plant roots.

Inorganic fertilizer

Inorganic fertilizers are produced artificially and include minerals or synthetic chemicals. Phosphorus, potassium, and other residues in inorganic fertilizers are often a product of mining. Inorganic fertilizers come in single-nutrient or multi-nutrient formulations. Multi-nutrient formulations include complete and balanced fertilizer substances, which contain nutrients like nitrogen, phosphorus, and potassium, as well as micronutrients such as calcium, magnesium, boron, and manganese.

Organic Fertilizers

Organic fertilizers are derived from plants and animals. The fertilizer enhances the soil with carbonic compounds vital for plant development as well as adds to the organic matter content of the soil. Which accelerates the propagation of micro-organisms, and modifies the physical and chemical characteristics of the soil.

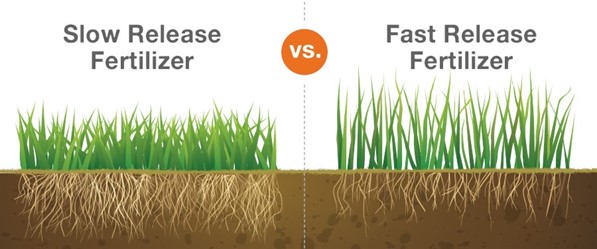

Slow-release fertilizer

Most commonly the uncoated fertilizer granules quickly release the nutrients into the soil, which causes the plant to have insufficient time to make use of the nutrition offered. Slow-release fertilizers release a small, constant quantity of nutrients over a certain period of targeted time. Most often, when a product is labeled as slow-release fertilizer it is coated with plastic resin or sulfur-based polymers which slowly breaks down when it comes into contact with water, heat, sunlight, and soil microbes, allowing a plant to capture the nutrients when required. The fertilizer industry uses artificial barriers, the aforementioned plastic resin or sulfur-based polymers, to control the dissolution rate. Coating layers on fertilizers are a widely used practice nowadays.

Legislation of non-Bio-degradable Fertilizer Coating

In 2015, however, the EU Commission launched its Circular Economy Action Plan which is the foundational policy towards a more resource-efficient economy in Europe. Among the main priorities of the plan is the reduction of plastic use and waste. The EU’s Fertilizing Products Regulation as a result of Circular Economy Action Plan sets the guidelines for slow-release fertilizers. Within these guidelines, the current polymer encapsulation systems won’t meet the scope of future restrictions.The industry must therefore develop a bio-degradable product before 2026.Delft Solids Solutions recently applied a new bio-degradable fertilizer coating which in part led to Kaumera coatings.

Introducing Kaumera

Kaumera is a new bio-based raw material that is extracted from the sludge granules that form during the Nereda® purification process. Due to its unique properties, Kaumera lends itself to multiple applications. It can repel and absorb water and it is fire retardant. It is also very suitable for coatings and composite materials. Currently, applications in agriculture prove to be very promising.

Environmental benefits

Kaumera, a bio-degradable coating developed to replace the traditional plastic coatings. Kaumera is extracted from wastewater and as a byproduct reduces the need to remove and process the sludge by 20- 35%. As a biodegradable, recyclable, and renewable sourced natural product, it is a potential solution and offers a positive effect on the strain of energy consumption and released CO2 emissions currently the largest contributor to greenhouse effect nowadays.

The Kaumera Partnership

The recovery of Kaumera from wastewater takes place within the National Kaumera Development Programme NKOP. In this program, the Vallei and Veluwe Water Authority, Rhine and IJssel Water Authority, the Dutch Foundation for Applied Research in Water Management (STOWA), Royal HaskoningDHV engineering consultancy, ChainCraft, Delft University of Technology, worked closely together and consulted with Delft Solids Solutions to introduce Kaumera.

All parties contributed part of their knowledge and expertise needed to retrieve, process, and market the new raw material. From laboratory research to full-scale recovery. In this way, the Water Authorities, the scientific community, and the business community work together on a sustainable, circular economy.

Bio-degradable Fertilizer Coating applied via drum coating

The coating drum consists of a rotary drum that rotates at a controlled speed, while fertilizer granules are continuously fed into the drum. Set on a certain angle, gravity helps to move the material through the drum in accordance with a set time. As material moves through the drum, a spraying system sprays the coating material onto the material bed. Due to the continuous movement, a uniform coating can be obtained that is homogeneously distributed over the large number of granules.Spray systems must be designed for optimal distribution of the coating agent, taking into account factors such as spray locations, nozzle types, bed depth, rotational speed, and so on. A high volume of elevated temperature air heats the fertilizer granules at around 60°C during their movement in the drum in order to attain relatively fast drying of the coating material thereby avoiding dissolution of the water-soluble fertilizer granules.

Coating quality control

After the coating process, the coating quality can be various depending on the coating material, process settings and granules size. Quality control on the coating is also a specialty Delft Solids Solutions offers by using different analytical methods.

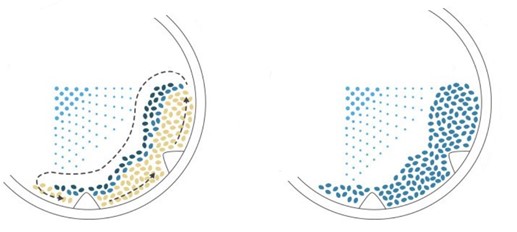

Coating morphology

Certain mass percentages of the coating material have been applied to the fertilizer granules. Different coating materials give quite a range of results on the coating morphology. Some of the coating show smooth uniform layers referred to as ‘good coating’ while other coatings may result in a broccoli pattern referred to as ‘bad coating’. The three conditions of good coating, bad coating, and uncoated granules are displayed in figure 4.

Figure 4. Coating morphology by using different coating materials.

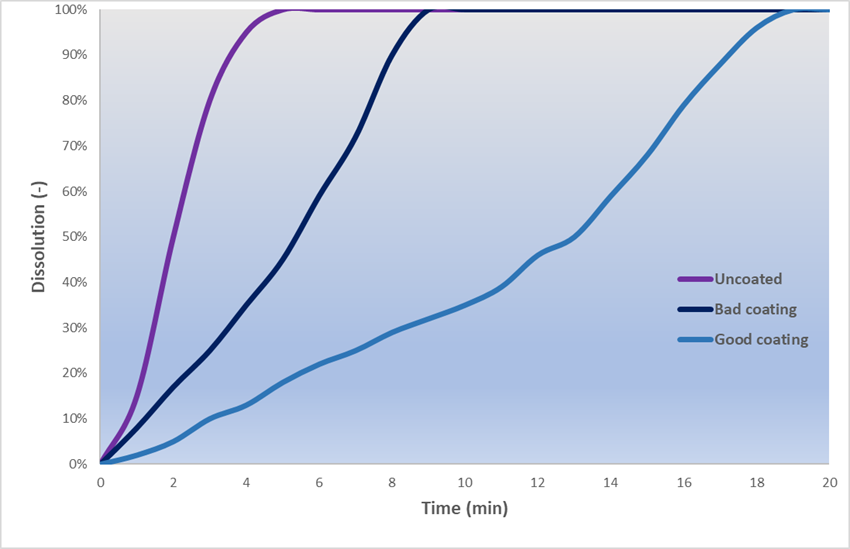

Dissolution test diagram

Aside from the morphology of the coating layer, another important parameter, that can determine the quality of the coating, is the dissolution rate. After the coating process, the differently-coated granules were initially screened in water of constant temperature for their performance. Their dissolution performance was monitored during which the coating layer deformed and fell apart in the water. The results of the so-obtained dissolution times have been listed below in Figure 5.

Figure 5, displays the dissolution results after 5 minutes in the solutions. The uncoated granules already show no particles while the coated granules keep shaped. Besides, the good coating granules keep more shape than the bad coating granules

Bio-degradable Fertilizer Coating research with Electron microscopy and Microtomy

In order to study the coating thickness and coating uniformity, slicing or microtomy can be applied to make adequate cross-sections and slices of the coated granules.

Subsequently, these slices can be studied by light microscopy or electron microscopy to visualize and quantify the coating thickness and to obtain information on the coating uniformity. With the increasing regulations, it has become important to develop the latest generation of bio-degradable fertilizer coating methods. The Delft Solids Solutions laboratory offers testing methods that can be employed to test many variables and fine-tune them to reach optimal product coatings.Optimization tools that are to be taken into account are rotational speed, coating feed rate, material feed rate, spray locations, and the tumbling flight design.

Delft Solids Solutions is capable of testing all of the variables mentioned above and more to gather the data necessary to help design a viable commercial-scale coating process. Delft Solids Solutions is a leader in the powder and granule field.

Our coating drum and spray systems are designed around the material to provide an optimized coating solution, tailor-made to your product’s needs.