As has been amply discussed Delft Solids Solutions has three primary pillars of business management: Consultancy, R&D and knowledge sharing through our academy ‘arm’.

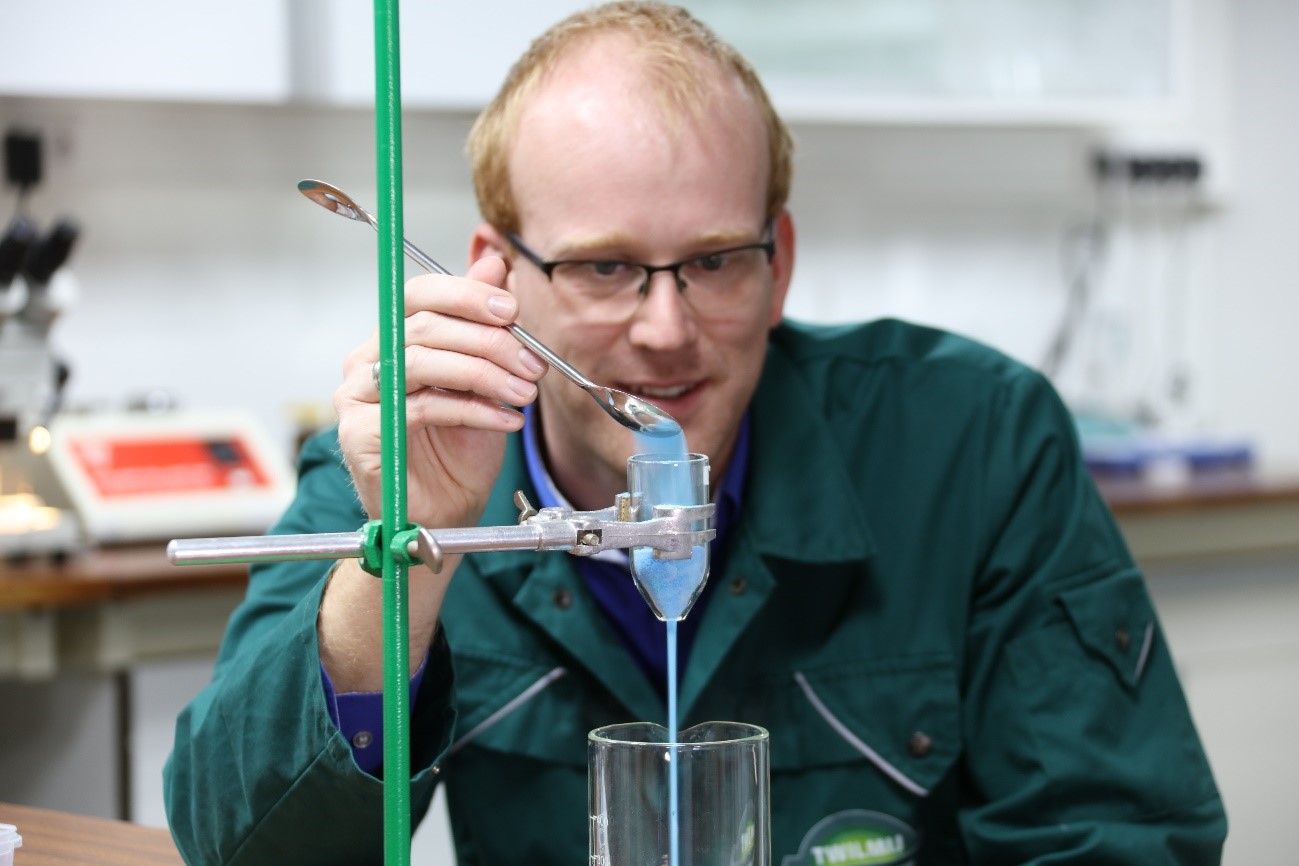

We had the pleasure of talking to Jan Kuperus van Twilmij. Thanks to his involvement with his organization, a collaboration has been established in the field of knowledge sharing, both internally aswell as externally. Delft Solids Solutions is proud that have been able to play a small role in this. We inter- viewed Jan about his role with Twilmij, what his work entails and about the substantive collaboration with DSS.

What kind of organization is Twilmij? What does the company specialize in?

Since 1963, Twilmij has been developing and producing high-quality cores and premixes for the European animal feed sector. Our nutritional team supports our customers in nutritional and product technical knowledge and experience. Twilmij has been part of DSM Nutritional Products since November 1st 2017.

What exactly does Twilmij produce?

At Twilmij we produce around 3000 different premix recipes on demand. Every nutritional question comes with a specific recipe. And if there is no ready-made answer, we will engage with our customer to come up with a suitable recipe that fits the desired requirements. We join forces with parent company DSM, world’s largest and most reliable vitamin producer. We are a strong proponent to sharing knowledge.In regards to a physically stable premix, aspects such as segregation, flow behavior and hygroscopicity (attracting moisture) are reviewed. My task is to map out these unwanted interactions and try to prevent them. Usually a chemically and physically stable premix is directly opposed to the nutritional composition and thus it can even occur that a premix recipe has to be split into 2 different recipes, whereby the raw materials that affect each other adversely no longer occur in the same recipe. This way, a chemically / physically desired premix recipe can still be produced while still meeting the nutritional requirements of the customer.As you can see, you have to be knowledgeable in many subjects and aspects of the production process and that is why the knowledge and support of Delft Solids Solutions is a good fit when it comes to the physical properties of the premix.

.

Could you tell us about yourself and what it is you do at Twilmij?

My name is Jan Kuperus, at Twilmij, I work as a premix and process engineer. My role is to provide customers with product technical information, whereby the chemical and physical stability of the premix is paramount.

How did you start working at Twilmij, and how long have you been at the company?

After studying biotechnology, specializing in process technology at Wageningen UR, I gained 3 years of work experience in algae research, in an algae production environment. During these 3 years it became clear to me that I would prefer to work in the food / animal feed sector and therefore started looking for a process technology position. Through my network I ended up at Twilmij, where they were looking for a premix and process technologist. Currently, I have been working at Twilmij with great pleasure for the past 3.5 years now.

.

What exactly do you do as a Premix and process technologist?

My role as a premix and process technologist is to inform the client about the chemical and physical properties of the premix.

The formulas are formulated based on nutrients, more often than not overlooking the composition aspects such as color, odor and stability of the bioactive ingredients, such as vitamins, yeasts and enzymes. Not only the composition, but also the process conditions at the customer base of operations influences the stability of the bioactive ingredients. My role as a process engineer is also to evaluate with clients to ensure the stability of the bioactive ingredients during their process conditions.

What was your primary reason to connect with DSS?

When I started at Twilmij, I quickly realized that powder handling and powder behavior is a unique field all on its own. Following this, we started looking for courses / workshops to increase our knowledge level. This ultimately led to the organizing of an in-company course by Delft Solids Solutions. Peers at Twilmij who frequently come into contact with powder behavior participated in the course. Through this a broader understanding / knowledge emerged within the company.

.

What was your primary challegence in regards to powder handling?

At Twilmij, the ideal image is to produce a premix while maintaining (or improving) a certain level of homogeneity and stability. In practice we come across certain cases where this level can’t be maintained, nor can it be explained directly as to why this is the case.For example in summer periods, customers regularly report that the premix shows bridging. Similarly it sometimes happens that the premix hardens in the customers bulk storage silos. Based on these reports, the effect of climate (humidity) on the flowability of the premix was examined.As a result of this research, some adjustments were made to the purchasing choice for certain raw materials, think of fewer hygroscopic ingredients. In addition, choices have been made to no longer recommend a certain combination of raw materials or to make clients aware of the limitations.You’ve mentioned you were looking for a deepening of knowledge which led you to the in-company training. Have you participated in any of the DSS seminars and if so which ones?We have been visiting various seminars, Powder & Particle Characterization day in 2018, the Powder (Non-) Flow Day and the Mixing day in 2016.

.

What do you think of the genral quality of the DSS in-company training?

The quality of the in-company training was very good, the main objective was to provide a basis of information in regards to what negative effects powders can cause in the production process and how to prevent or solve them. What also came to light is that sometimes the solutions isn’t necessarily found in the premix composition, but might have a technological solutions, such as silo and transport system design.

Powder technology contains so many different aspects, even though the course was specifically focused on our areas of interest, further deepening of certain subjects is still desirable. For that reason we continually visit relevant seminars to gain more in-depth knowledge of those specific topics.

I also see the seminars as a way to keep up-to-date on new developments and knowledge of the powder handling sector. Moreover, I find the lunch conversations of particularly value. These luncheons often show, despite the different industries where the participants work, that we all have similar powder handling challenges.